| Author |

Message |

Luis Constantin

| | Posted on Thursday, January 30, 2003 - 07:53 pm: |

|

Here is one I bet not many have noticed. The passenger side (right or driver side for our Brit friends) of the rear axle sets approx 1 inch further back than the left side on the Disco 1. The car has never been in a collision. I have an OME kit installed. We changed all the bushings out,(installed the blue ones.) The dealer can't figure it out, and some people I talk to have never heard of this. Has anyone else had this issue ? |

Samuel L.

| | Posted on Thursday, January 30, 2003 - 07:58 pm: |

|

That is the camber adjustment. You need to turn the camber nut probably about 6 times. This off-camber mode that you are currently seeing was probably set up for roadracing. This would help on turning, especially on right hand turns |

Carter Simcoe

| | Posted on Thursday, January 30, 2003 - 07:59 pm: |

|

they designed the rear axle to be "cock-eyed" so that you have better wheel articulation. They are all like that! |

OLIVER CLOTHSOFF (Everythingleaks)

| | Posted on Thursday, January 30, 2003 - 08:01 pm: |

|

I have had these vehicles on an alignment machine and almost none of the rear ends fall into spec. I don't remember which way they were off but almost all of them show in the red. Even the '03 is like that.

The more things change . . . |

Carter Simcoe (Carter)

| | Posted on Thursday, January 30, 2003 - 08:05 pm: |

|

Actually imposter, mine IS off a little judging from the distance from the tires to the wheel wells (not quite an inch though) |

muskyman

| | Posted on Thursday, January 30, 2003 - 08:14 pm: |

|

the axles arent suposed to be parralel on a straight axle truck, the have whats called torque angle built into them so when they are under load the go straight. |

Carter Simcoe (Carter)

| | Posted on Thursday, January 30, 2003 - 08:16 pm: |

|

that makes sense |

Richard

| | Posted on Thursday, January 30, 2003 - 08:43 pm: |

|

That is the stupidest thing I have ever heard "torque Angle" I hope that you are joking  otherwise I have some words...... otherwise I have some words...... |

muskyman

| | Posted on Thursday, January 30, 2003 - 09:22 pm: |

|

let me hear your words! |

Paul H

| | Posted on Thursday, January 30, 2003 - 09:28 pm: |

|

Yeah, and apparently when you are going down the road coasting, (no torque) the axles are misaligned. That has got to be the most ridiculous thing I've heard in quite a while. |

muskyman

| | Posted on Thursday, January 30, 2003 - 09:31 pm: |

|

when torque on a drivline is applied the vehicle body rotates if viewed from the front or rear,when this happens the axles relative position to each other changes

now I am not an expert in this but I happen to know someone who builds chassis's for a living and is a highly respected expert in race car chassis building. it is a key factor in having a torque free chassis.

but it real |

Ron

| | Posted on Thursday, January 30, 2003 - 09:32 pm: |

|

You said disco I, something is bent.

Alignment on rovers is terrible but 1in is too much, the only other thing I can think of is the trailing arm bushes have been mounted wrong.

Ron |

muskyman

| | Posted on Thursday, January 30, 2003 - 09:33 pm: |

|

paul,

yes they are slightly misaligned. thats why you need castor and toe setting to over power the tendencie of a vehicle to pull.

mm |

muskyman

| | Posted on Thursday, January 30, 2003 - 09:34 pm: |

|

no its no where near 1" |

Richard

| | Posted on Thursday, January 30, 2003 - 09:34 pm: |

|

There is no way that the axles are designed not to be parallel regardless of the axle type. I don't know what your profession is but I can guarantee that it is not an engineering or technical field related to automobiles and if it is then let me know so I can stay 10 miles away from anything that you could come in contact with. |

Paul H

| | Posted on Thursday, January 30, 2003 - 09:41 pm: |

|

This misalignment of the front/rear axles has nothing to do with the front end alignment of a car. Like I said before, if that is the case, we would be going down the road cock-eyed while coasting. As far as a torque free chassis goes- you are preloading the chassis by misaligning the axles even before torque is even applied. Don't get me wrong here, I am no car frame specialist here.------Just a mechanical engineer with a little common sense |

Richard

| | Posted on Thursday, January 30, 2003 - 09:41 pm: |

|

it is generally referred to as "thrust angle" and there may be a small (fraction of an degree) thrust angle in a vehicle but not by design. Manufactures will state a tolerance to account for manufacturing variances but the design would be for the axles to be parallel |

muskyman

| | Posted on Thursday, January 30, 2003 - 09:48 pm: |

|

i wish I had a copy of Maurice Olley's book here I'd give you a more complete explanation...let me see if I can find it online... |

muskyman

| | Posted on Thursday, January 30, 2003 - 09:54 pm: |

|

yes richard I have heard it called thrust angle as well.

my first expierience with it is when I was taking measurements of a suspect frame on a lazer frame straightening devise, I was all paranoid because the measurments from side to side werent the same. thats when my friend the chassis builder explanned to me they arent suposed to be. he then went into a very long detailed explanation of it.

like I said above I am not an expert chasic builder...but it does exsist |

muskyman

| | Posted on Thursday, January 30, 2003 - 10:01 pm: |

|

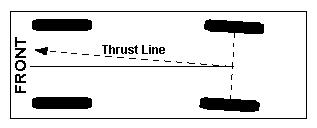

thrust angle is defined as the deviation between the bisector of the total rear toe angle of the vehicle (the thrust line) and the vehicle centerline.

this is from a exceprt of maurice olley's book |

Richard

| | Posted on Thursday, January 30, 2003 - 10:02 pm: |

|

I agree with you, Thom, that it exists I guess my argument is that it is not part of the design just part of the exactness (for lack of a better term) of the manufacturing process. My understanding is that the misalignment between front and rear axles can be as much as .2 degrees which would be the tolerance i.e. 0.0+- 0.2 degrees would be an acceptable product. |

Richard

| | Posted on Thursday, January 30, 2003 - 10:03 pm: |

|

Do you have a link to the website (olley's book)? |

muskyman

| | Posted on Thursday, January 30, 2003 - 10:08 pm: |

|

i just did a google search of his name, i have heard his name about a million times from my friend I guess he's the founding father of most of the chassis theory people use today.

let me go find a link to the definitions page i pasted that from |

Paul H

| | Posted on Thursday, January 30, 2003 - 10:18 pm: |

|

Musky,

Yes, Olley was one of the forerunners in chassis design. He designed chassis for GM and Rolls-Royce. |

thom mathie (Muskyman)

| | Posted on Thursday, January 30, 2003 - 10:21 pm: |

|

heres another I just came across

Thrust angle is the direction that the rear wheels are pointing in relation to the center line of the vehicle. If the thrust angle is not zero, then the vehicle will "dog track" and the steering wheel will not be centered. The best solution is to first adjust the rear toe to the center line and then adjust the front toe. This is normally done during a 4-wheel alignment as long as the rear toe is adjustable. If the rear is not adjustable, then the front toe must be set to compensate for the thrust angle, allowing the steering to be centered.

still trying to find that definition page...trust me i didnt make it up...i cant sound that good |

thom mathie (Muskyman)

| | Posted on Thursday, January 30, 2003 - 10:22 pm: |

|

|

Richard

| | Posted on Thursday, January 30, 2003 - 10:24 pm: |

|

Here is a simple way to look at it. the center line of the car is essentially down the center of the car and the thrust angle is the angle from center that the rear wheels will push the car. so front wheels are goign straight and the rear wheels are pushing 1 degree (example) to the left. You would want the rear wheels to push down the center line and not 1 degree from that. |

thom mathie (Muskyman)

| | Posted on Thursday, January 30, 2003 - 10:25 pm: |

|

third times the charm

|

Richard

| | Posted on Thursday, January 30, 2003 - 10:25 pm: |

|

I must have been typing mine as you submitted yours. |

Paul H

| | Posted on Thursday, January 30, 2003 - 10:27 pm: |

|

We are arguing about separate things here Musky. My argument is not that thrust angle exists, but that it is not designed into a chassis. The adjustments to alignment are meant to remedy this problem. |

Richard

| | Posted on Thursday, January 30, 2003 - 10:28 pm: |

|

It seems as though we are on the same page then huh? We agree on everything except whether or not the phenomenon is designed into the system. |

muskyman

| | Posted on Thursday, January 30, 2003 - 10:32 pm: |

|

well that was my point, people are alarmed when there car goes in for a "four wheel" alignment and the side to side numbers dont match. they are not suposed to . and different cars have different amounts based on a number of other factors.

this one reason why I always tell people you cant just start cutting and welding and expect awsome results...there really is solid science behind why things are where they are in a chassis |

muskyman

| | Posted on Thursday, January 30, 2003 - 10:35 pm: |

|

its not designed in...its designed out by aligning the axles properly

and properly is not parralel...that was what my original post was about |

muskyman

| | Posted on Thursday, January 30, 2003 - 10:36 pm: |

|

yes Richard I think we are on the same page |

Richard

| | Posted on Thursday, January 30, 2003 - 10:39 pm: |

|

but didn't we just agree that parallel is proper if they could manufacture the axles parallel. Idealy they axels would be parallel and then there would be no need for alignment with respect to that specific condition. It is not cost feasible to manufacture the axles parallel (o tolerance) |

muskyman

| | Posted on Thursday, January 30, 2003 - 10:45 pm: |

|

not as it has been explained to me

parralel makes the thrust angle deviate from the centerline. so they calculate where they need to be to move the thrust line to the vehicle centerline.

on straight axle vehicles there is no rear toe adjustment so you need to misalign the rear axle to put the thrust line on the centerline then use front toe to make the car not dog track |

Richard

| | Posted on Thursday, January 30, 2003 - 10:50 pm: |

|

With the wheels perpendicular to the axels and the axles parallel to each other, the thrust angle should be 0 (thrust line parallel to centerline) |

Ron

| | Posted on Thursday, January 30, 2003 - 10:58 pm: |

|

"on straight axle vehicles there is no rear toe adjustment so you need to misalign the rear axle to put the thrust line on the centerline then use front toe to make the car not dog track"

Thrust angle whatever. You mind telling me where they built in the thrust angle into a rover chassis?

Answer: They didn't. check the chassis specs.

Ron |

muskyman

| | Posted on Thursday, January 30, 2003 - 11:04 pm: |

|

yes I believe thats true in a static state but under load it changes due to chassis rotation. or at least thats how its been explained to me.

and thats why they use front toe to quell the torque induced steer.

thats also why all the auto builders hate straight axles because no matter what you do you always have shortcommings

in the morning I'm gonna call my chassis buddie and get a refresher course he will be able to explain it in under 2000 words |

muskyman

| | Posted on Thursday, January 30, 2003 - 11:05 pm: |

|

why dont you post them ron |

muskyman

| | Posted on Thursday, January 30, 2003 - 11:09 pm: |

|

we are talking about very small numbers here...it could be the difference of less then a 1/8" hidden in single suspension mount or link |

Ron

| | Posted on Thursday, January 30, 2003 - 11:15 pm: |

|

I don't have a scanner.

But basically the mounts on the left are the same as the mounts on the right. No difference in spacing or anything. The measurements are given in the manual.

As far as your comment about under load you have to remember than on a disco I the rear suspension is set up in such a way that the axle neither pulls left or right under any torque. The only way a change in thrust angle would occur was if one side was higher than the other, changing the effective length of the trailing arms and inducing some thrust angle. The amount of chassis rotation is basically nil. We are not talking about a C section CJ-2a frame or a beford lorry.

As far as front allignment it is really interesting as LR can't make up its mind whether it wants in or out.

While all this is very interesting and may be true for other vehicles LR did not build it into its chassis design (which is now 33 years old).

Ron |

Paul H

| | Posted on Thursday, January 30, 2003 - 11:15 pm: |

|

Musky, quit trying to maintain your position by making your so called "designed torque angle" miniscule. Reality is, that it is not designed into a vehicle no matter how small it is. If it does exist however, it is overcome by alignment adjustments. |

Richard (Richard)

| | Posted on Thursday, January 30, 2003 - 11:18 pm: |

|

As a degreed mechanical engineer I can't imagine that an engineer would design the axle misalignment for maximum or heavy acceleration when 75 - 90 % of the vehicle life will see constant velocity. Acceleration will twist the axle Circumferentially but I am not sure that I buy into the axle twisting transversly (with respect the the car) if it did twist as i mentioned about I would be surprised if they would design for that as the change in angle would be extremely small with relatively little affect.

My $.02 |

muskyman

| | Posted on Thursday, January 30, 2003 - 11:39 pm: |

|

I would guess its not designed to compensate for full throttle I would think it is designed in for constant load. and yes constant load does induce chassis position changes from its static position.

as engineers i think you wont argue otherwise

ron like I said we are talking very small numbers here. it could be as small as moving the bolt holes under one rear spring plate on an axle and they may also have changed it over and over based on any number of things. they also may not list it in manuals because recreating it to any accuracy after the fact would be tough I would guess.

on race car chassis I have seen my friend lay out locations or hangers and mounts with a lazer to ensure accuracy. and he is the same guy that stressed how important this is over and over?

well I aint gonna keep argueing a point I'm not a "degreed expert" in

but it does exsist has been written about since the 1930's and is a design concern of companies building straight axled vehicles.

well hey fun thread just the same ...been a while since people talked tech in the tech section instead of the bull shit the last few weeks

peace

thom |

Carter Simcoe (Carter)

| | Posted on Friday, January 31, 2003 - 12:23 am: |

|

Hey Thom, I for one would still be willing to get within 10 miles of your Scout  |

Richard

| | Posted on Friday, January 31, 2003 - 12:10 pm: |

|

The axle does not twist or rotate transversly (left to right) under constant power (constant velocity)i am not even sure that it does under acceleration to a degree that would not affect anything. if they did offset thrust angle on purpose then the vehicle would not drive correctly under coasting and constant velocity situations. |

Randy

| | Posted on Friday, January 31, 2003 - 12:22 pm: |

|

I do not agree with any forementioning of land rover designing for thrust angle. I also am a degreed mechanical engineer, and I do believe that modifications to a chassis are made in order to compensate for traction problems. However, modifications are made for acceleration under full throttle as in drag racing.

Muskyman, your thrust angle picture shows a rear wheel drive vehicle. Land rovers are all wheel drive, if thrust angles were built in then the front would also need a thrust angle due to the all wheel drive.

I believe the difference in measurement is only a tolerance issue on a factory vehicle. It would be very costly and time consuming to ensure every land rover has a perfectly parrallel axle setup. Thats the whole purpose for tolerances: close enough without compromising cost.

Randy |

muskyman

| | Posted on Friday, January 31, 2003 - 12:37 pm: |

|

I talked to my friend the chassis builder first thing today and he said its pretty simple

he said think roller skate , any tilting of the chassis is going to move the thrust angle of the vehicle.the harder scceleration you are dealing with the more compensation needed.

then he said that companys used to use axle missalignment as the sole means but it is a sloppy way of doing it.

he then asked if the coils are all the same height and spring rate.

I said no that my factory springs one front spring is slightly shorter then the other.

he said well there you have it Land rover must be using there springs to compensate and control thrust angle.

is he right?...good question, but I tend to think he is.

thom |

Milan (Milan)

| | Posted on Friday, January 31, 2003 - 01:19 pm: |

|

Maybe they design this into race cars that go full throttle most of the time but this is the first time I hear of it being "designed" into road and off-road going passenger vehicles. I don't buy the spring used as an adjustment either. All chassis specs I have seen for LR and for Jeep and for Ford had equal measurements for both sides and some of these are taken off suspension mounts. It is these measurements that are used to straighten bent frames back to spec. You do allignment to make the car go straight and track well. I still believe this is the same even for race cars as even there I'd imagine the chasis would be built with identical measurements and then suspension adjusted if need be to make the car do whatever. I mean, the race mechanics adjust this for every track and every race. Changes are constant (heheh I like that statement  ). For regular road-going vehicles I believe it's designed to be as even as possible all the time to account for all variations in driving conditions, different loads, etc. LR's different height springs would also worsen the thrust angle under torque on NAS vehicles, no? The passenger side being lower, then getting a bit equalized by the driver's weight and then again squishing the right rear under torque. I just don't see it. ). For regular road-going vehicles I believe it's designed to be as even as possible all the time to account for all variations in driving conditions, different loads, etc. LR's different height springs would also worsen the thrust angle under torque on NAS vehicles, no? The passenger side being lower, then getting a bit equalized by the driver's weight and then again squishing the right rear under torque. I just don't see it. |

Carl (Cdoug3)

| | Posted on Saturday, February 01, 2003 - 11:29 am: |

|

With those comments I don't think I would let the guy near any of my cars! |

Kyle

| | Posted on Saturday, February 01, 2003 - 12:03 pm: |

|

I wouldnt say "designed in" , I would say "Expected" . Mass production cant be compared to a guy hand building a chassis to race. There are "Tollerances" on mass produced items and I think that is what Musky is trying to say. It not being exactly perfect is not exactly "designed in" but its certainly expected. The frame ears for the trailing arms on these things are also so damn weak it doesnt take much to bend them and its not very evident that you have. You have to look at a perfect set to see that yours are bent.

Kyle |

Luis Constantin

| | Posted on Sunday, February 02, 2003 - 01:13 am: |

|

Personally, I don't think Rovers produce enough torque to have an effect in thrust angle. Even on my prostreet Cutlass that I used to have, the only effect the torque would have on the axle was to increase the pinion angle upwards. It would also have a tendency to twist the body and the frame, which is why you preload a suspension in the first place, so that when the car pulls the front wheels off the ground, the car's chassis will remain staight and so will the car through the 1/4 mile, hopefully. None of which we should ever have to worry about in a Rover. |

Lance (Ely)

| | Posted on Sunday, February 02, 2003 - 08:22 am: |

|

Kind of funny how pinion angle didn't come up til now, what with all the preoccupation with lifting in general and dollars/pounds spent tying to remedy resultant vibes. Perhaps, it's so well understood that it's tacit by now?

Also, vehicle chassis designed to run the 1/4 are going to be running spools, No? The calcs with a spooled rear compared to an open (usually) AWD system- apples to oranges. |