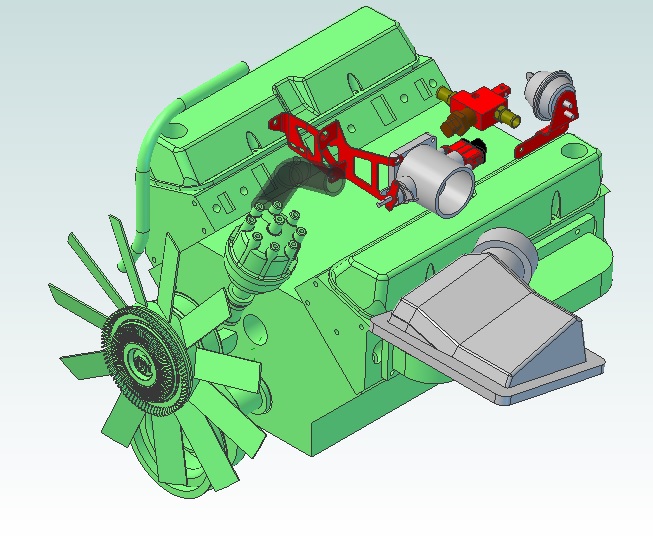

every once in a while I see reference to this usually on foreign websites, but never any pics and 14cux is almost always ditched for something else. Figure I'll give this a try since the engine seems to really only have any grunt above 2500 RPM it'll be nice to lower that powerband.

issues

1. throttle cable

2. kickdown cable

3. cruise control diaphgram

4. idle air control

5. coolant temperature sending unit (gauge)

6. coolant temperature sending unit (ecu)

7. thermostat housing

8. fuel rail

9. TPS sending unit

10. throttle body to intake manifold duct

throttle body, kickdown, and cruise control will be dealt with by making custom brackets and swapping to a cable drive cruise control like a D2. Ashcroft makes a really long ZF kickdown cable for custom swaps that I have on order. Grabbed a 200/300 TDI throttle cable that I hope is long enough, if not theres always the 98 50th edition 4.0 defender cable, but thats likely way to long.

idle air will be a custom housing where the D2 IAC went

ECU temp sensor threads in place of the Bosch sending unit. There is an untapped boss on the left side of the lower manifold that the gauge sending unit fits

Thermostat housing will take some machine work. One of the 3 bolt holes lines up, there is a casting boss for the second bolt, blind drill and tap takes care of that. The pocket for the thermostat will have to be farmed out to a shop with a mill with some Z height, I can't do that at home and don't want to mess it up.

Early range rover fuel rail looks like it fits. I'll lose the schraeder valve, but I'm sure I can work around that. Feet either need to be hacked up or removed and re-brazed in the correct location.

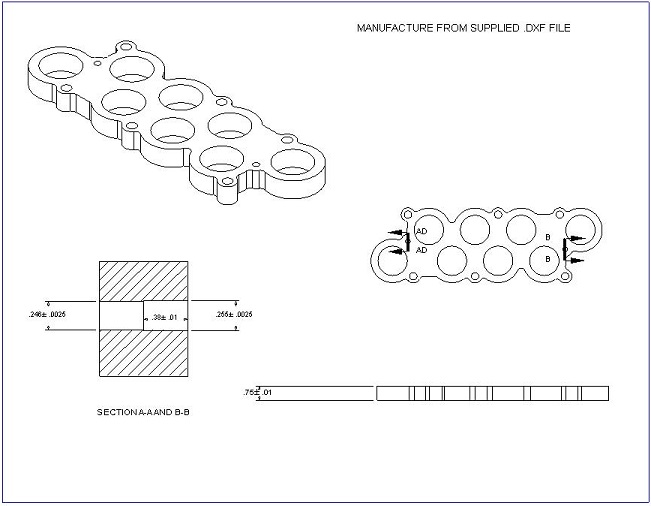

TPS needs an adapter, got that designed and it'll be printed out of high heat tolerant material

Throttle body to MAF duct work is going to be an ugly hack. I'll figure that out later.

The plan so far:

issues

1. throttle cable

2. kickdown cable

3. cruise control diaphgram

4. idle air control

5. coolant temperature sending unit (gauge)

6. coolant temperature sending unit (ecu)

7. thermostat housing

8. fuel rail

9. TPS sending unit

10. throttle body to intake manifold duct

throttle body, kickdown, and cruise control will be dealt with by making custom brackets and swapping to a cable drive cruise control like a D2. Ashcroft makes a really long ZF kickdown cable for custom swaps that I have on order. Grabbed a 200/300 TDI throttle cable that I hope is long enough, if not theres always the 98 50th edition 4.0 defender cable, but thats likely way to long.

idle air will be a custom housing where the D2 IAC went

ECU temp sensor threads in place of the Bosch sending unit. There is an untapped boss on the left side of the lower manifold that the gauge sending unit fits

Thermostat housing will take some machine work. One of the 3 bolt holes lines up, there is a casting boss for the second bolt, blind drill and tap takes care of that. The pocket for the thermostat will have to be farmed out to a shop with a mill with some Z height, I can't do that at home and don't want to mess it up.

Early range rover fuel rail looks like it fits. I'll lose the schraeder valve, but I'm sure I can work around that. Feet either need to be hacked up or removed and re-brazed in the correct location.

TPS needs an adapter, got that designed and it'll be printed out of high heat tolerant material

Throttle body to MAF duct work is going to be an ugly hack. I'll figure that out later.

The plan so far: