| Author |

Message |

mongo

| | Posted on Sunday, November 03, 2002 - 06:53 pm: |

|

Any idea's... |

Greg Davis (Gregdavis)

| | Posted on Monday, November 04, 2002 - 10:35 am: |

|

Frank, whatcha up to? New rear shaft? |

mongo

| | Posted on Monday, November 04, 2002 - 10:41 am: |

|

yup...can't get the f@#$&^ thing off, now it's raining...so much for a QUICK project...any idea's?

Frank |

Paul T. Schram (Paulschram)

| | Posted on Monday, November 04, 2002 - 11:03 am: |

|

Use a socket (might need a deep well) that will fit over the peg, insert an 8X1.5 (I think that pitch is right, it might be 1.0) bolt through a washer and through the socket into the peg. Hold flange stationary, tighten bolt, flange might pull out.

This topic has been discussed to a great extent and this seemed like the most elegant solution I've heard yet. |

mongo

| | Posted on Monday, November 04, 2002 - 11:07 am: |

|

Thanks Paul...I just finished searching the archives...let u know if it works...

Frank |

Greg Davis (Gregdavis)

| | Posted on Monday, November 04, 2002 - 11:59 am: |

|

Frank, if it makes you feel any better, I couldn't get mine off and had to take it to the dealer! Good luck with it, and let us know if Paul's method worked. |

Paul T. Schram (Paulschram)

| | Posted on Monday, November 04, 2002 - 12:08 pm: |

|

As much as I'd like to take credit for it, the method I described above was posted here by somebody else.

Needing to do this myself, I have paid close attention to how others have accomplished the task. I was all set to make a tool until I saw the socket method. It was too elegant for me to make a tool when it is that easy.

Almost as easy as it was to make the Toyota clutch alignment tool last night! Without a doubt, the easiest assembly I've ever done. |

mongo

| | Posted on Monday, November 04, 2002 - 04:29 pm: |

|

This is a F#$%^&*& PIA  ...The socket didn't work, any other ideas? ...The socket didn't work, any other ideas?

Frank |

Fred Phillips (Fphillips)

| | Posted on Monday, November 04, 2002 - 05:18 pm: |

|

I encountered this same problem a couple of weeks ago when I changed the input pinion seal on the rear differential. I tried the "socket tool" method and managed to break off a bolt in the end of the peg. After drilling out the broken bolt I tried again with a higher quality bolt and heated the od of the flange with a propane torch. The heat was the secret. The peg came out quite easily. On my '94 it was only held in with loctite. After I cleaned both mating parts the peg was a slide fit. I reinstalled with a green loctite. |

mongo

| | Posted on Monday, November 04, 2002 - 05:32 pm: |

|

Yup, that just happened...will try again in the am...goin' to the bar for a couple of pints..

Cheers'

Frank |

Blue (Bluegill)

| | Posted on Monday, November 04, 2002 - 06:31 pm: |

|

heat & bang bang |

Blue (Bluegill)

| | Posted on Monday, November 04, 2002 - 06:36 pm: |

|

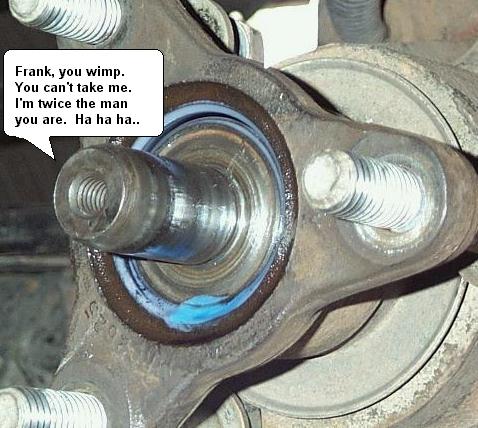

damn, now the peg is mocking you Frank.....you gonna stand for that?

|

muskyman

| | Posted on Monday, November 04, 2002 - 06:56 pm: |

|

man its times like this that having a drawer full of all shapes and sizes of pullers really comes in handy.

but I also have to say using just the right puller for the job is very anti-climatic put it in place verrrrrr with the impact boom done

blue...once again kudos on having just the right pic...lol |

Eric Ratermann (Ericrat)

| | Posted on Monday, November 04, 2002 - 07:10 pm: |

|

I used a slide hammer that I think I got from Napa. It isn't a body hammer but a slide hammer and puller set up.

There is a "cone" that threads onto the front of the slide. I had to drill the hole in the front of the cone open just a bit to fit the 8mm bolt and Smack Smack Smack.

It worked for me anyway.

Eric |

muskyman

| | Posted on Monday, November 04, 2002 - 07:20 pm: |

|

well if you have no puller a loop of chain and a high lift can make a damn strong puller/slide hammer

I have used it on the trail popping off a rusted frozen spindles to change broken stub shafts a number of times |

mongo

| | Posted on Monday, November 04, 2002 - 07:46 pm: |

|

Blue, your not a well man...I'm going back to the bar...maybe a hangover will provide some inspiration, or help unlock some unseen forces that I don't know I have...

cheers,

Frank

ok I'm lyin', why to many cute chicks at the bar... |

mongo

| | Posted on Wednesday, November 06, 2002 - 10:23 am: |

|

Ok, the piece of shit still won't come off!  I'm ready to use some c4 to if that will break it loose. I'm ready to use some c4 to if that will break it loose. Any other suggestions before I take it to the shop... Any other suggestions before I take it to the shop...

Frank |

muskyman

| | Posted on Wednesday, November 06, 2002 - 10:41 am: |

|

bolt one end of a 4' length of chain toone of the ears of the flange and the other end to another ear.

then put your high lift lifting hook into the loop the chain formed

then use the weight of the high lift to rip it off by banging the highlift forward against the loop pulling the flange.

it will be a primitive slide hammer but it will work |

mongo

| | Posted on Wednesday, November 06, 2002 - 10:48 am: |

|

I'll try it...

Thanks

Frank |

Greg Davis (Gregdavis)

| | Posted on Wednesday, November 06, 2002 - 11:40 am: |

|

Frank, just read the new tech article. It tells you how to remove it.

Sorry. Couldn't resist! I'm sorry you're having such a hard time. That's why I ended up at the dealer as well. |

Blue (Bluegill)

| | Posted on Wednesday, November 06, 2002 - 11:46 am: |

|

wait - is it the centralizing peg that's stuck tight, or is it the pinion flange? The peg covers the pinoin nut. If the pinion nut is still there (under the peg), then the pinion flange ain't goin nowhere, no matter how hard you hammer on the flange. |

Rob Davison (Pokerob)

| | Posted on Wednesday, November 06, 2002 - 12:01 pm: |

|

just use your teeth... thats what i always do.

rd |

mongo

| | Posted on Wednesday, November 06, 2002 - 12:21 pm: |

|

it's the peg, not the pinion flange. So that won't work. I haven't been beating the flange, just the peg...I wonder when the gears were installed if they buggered up the peg when it was re-installed...this is a royal PIA...I just called the LR dealer to see if i can "borrow" the tool...

Frank |

Blue (Bluegill)

| | Posted on Wednesday, November 06, 2002 - 12:33 pm: |

|

A box of krispy kremes early in the morning should increase your odds with the dealer. But if they don't let you borrow the tool, then you can rig up a similar tool with a few pieces of steel and a bolt that fits into the threaded end of the damn peg (what did Paul say it is....M8 x 1 or 1.5 pitch?). Use the pinion flange ears as the rigid base, and stack your steel and make a bridge a couple inches over the end of the peg. If you can tack weld it together, all the better. Drill a hole in the middle of the bridge, insert your bolt, and start torquing...the peg should pop off. |

mongo

| | Posted on Wednesday, November 06, 2002 - 12:53 pm: |

|

This made me laugh...

"You'll probably find that your centralizing peg is stuck in place. There is a special Land Rover tool (really just a puller) to remove a stuck peg. You should be able to think of a creative way to pull your peg off if it's stuck. Luckily, mine was loose."

this really sucks...

frank |

Blue (Bluegill)

| | Posted on Wednesday, November 06, 2002 - 12:59 pm: |

|

well, if I had the misfortune to encounter a stuck peg, I would have solved the problem and you'd be seeing it in living color. Luckily, mine was loose.  sorry mongo! sorry mongo!

I think that Garrett Porterfield was able to borrow the tool from the dealer. I meant to include the LR tool numbers for the peg and for the pinion nut in the tech article - I'll grab that info from my manual tonight and post it - maybe Ho will update the tech page. |

danc

| | Posted on Wednesday, November 06, 2002 - 06:37 pm: |

|

I made the special tool you need Frank. If it's not too late, I can let you borrow it. I'm in Seattle, so there will be some shipping time involved. Other than that? A slide hammer? Lots of heat (you'll have to change your oil seal for sure, though). If you don't need the 3 bolt flange, what about getting a composite cut off wheel and an air grinder and just take the whole frikin' flange forward of the nut off?????? |

Blue (Bluegill)

| | Posted on Wednesday, November 06, 2002 - 06:42 pm: |

|

"If you don't need the 3 bolt flange, what about getting a composite cut off wheel and an air grinder and just take the whole frikin' flange forward of the nut off??????"

now I'd call that creative...LOL |

mongo

| | Posted on Wednesday, November 06, 2002 - 06:52 pm: |

|

Creative...I'd say so...thanks for the offer but I finally got the f%^&* thing off  . After I got the peg out, it took about a hour to finish the install...Tomorrow I get the new the shoes mounted (285/75 Yokohama Geolander MT)...I've gotta stop spending $$$ on this thing... . After I got the peg out, it took about a hour to finish the install...Tomorrow I get the new the shoes mounted (285/75 Yokohama Geolander MT)...I've gotta stop spending $$$ on this thing...

Cheers,

Frank |

Clif Ashley (Cta586)

| | Posted on Wednesday, November 06, 2002 - 07:02 pm: |

|

What technique finally got it out? |

Blue (Bluegill)

| | Posted on Wednesday, November 06, 2002 - 07:06 pm: |

|

my money's on the BFH... |

Clif Ashley (Cta586)

| | Posted on Wednesday, November 06, 2002 - 07:10 pm: |

|

BFH? Sorry. |

mongo

| | Posted on Wednesday, November 06, 2002 - 07:14 pm: |

|

a lot of  and a really BIG F$%^&* HAMMER...just kidding, I used a couple of pieces of steel,some well placed heat and the socket. It came loose with only a little persuation from a hammer. When it was re-installed after the gear change, they used a little bit to much locite... and a really BIG F$%^&* HAMMER...just kidding, I used a couple of pieces of steel,some well placed heat and the socket. It came loose with only a little persuation from a hammer. When it was re-installed after the gear change, they used a little bit to much locite...

Frank |

muskyman

| | Posted on Wednesday, November 06, 2002 - 07:19 pm: |

|

my bad...thought you had got the peg out and where trying to pull the flange itself. |

mongo

| | Posted on Wednesday, November 06, 2002 - 07:23 pm: |

|

thanks, help and suggestions are always welcome muskyman...I now have new found respect for a 3 pound sledge...

Frank |

Greg Davis (Gregdavis)

| | Posted on Thursday, November 07, 2002 - 09:37 am: |

|

Frank, we want pictures when you get your 285's on! I hope you're as happy with your Yoko's as I am.  |

Paul T. Schram (Paulschram)

| | Posted on Thursday, November 07, 2002 - 10:01 am: |

|

Again, another situation where the blue speed wrench was called for. I've begun to think that the torch is the special Land Rover tool often referred to! I've had to use the torch on things I'd rather not share the stories of to fix my Rover.

Glad you got it off Frank.

Paul |

Rick Lindgren (Slacker)

| | Posted on Thursday, November 07, 2002 - 12:00 pm: |

|

Frank, what kind of driveshaft did you put on? Something salvaged, or something custom made?

Rick |

mongo

| | Posted on Thursday, November 07, 2002 - 12:17 pm: |

|

Greg,

I get the beast back in a couple of hours...I'll try and post some pic's

Paul,I'm with ya on that...seems to come apart better with a little

Rick,

It's a drive shaft from Bill at Great Basin Rovers. I got it when I put the the TT's,4.11's and HD rear axle's...

I gotta stop spendin' $$$$ on this thing...

Cheers,

Frank |

Greg Davis (Gregdavis)

| | Posted on Thursday, November 07, 2002 - 02:11 pm: |

|

Frank, do me a favor and e-mail me. I've got a few questions about your HD axles and such. |

mongo

| | Posted on Thursday, November 07, 2002 - 02:23 pm: |

|

greg, you'll have mail shortly...

Frank |