| Author |

Message |

Robert Sublett (Rubisco98)

| | Posted on Tuesday, July 23, 2002 - 10:08 pm: |

|

Hello all, received my OME shocks/springs today from Nathan and have a small problem. Just thought I'd run it by you guys first. I recieved the HD springs for the front and rear HD-751 & 762's. The shocks I recieved were N44 HD's for the rear and N45F for the front. I don't have an aftermarket bumper or winch and won't have a winch most likely. An ARB bumper is a possibility in the future. My question is will this set-up be alright or should I send back the N45F's for the N115's? I do often have lots of weight in the rear of the Disco. Thanks in advance.. Robert S |

gp (Garrett)

| | Posted on Tuesday, July 23, 2002 - 10:30 pm: |

|

my current setup is OME super HD's all around and don't have a winch/bumper up front. rides fine for me. but i am putting on a bumper/winch this coming weekend. so i can't see what would be wrong with that setup. |

Robert Sublett (Rubisco98)

| | Posted on Tuesday, July 23, 2002 - 10:38 pm: |

|

Just found this on EE

"For the Defender 90, Defender 110, Discovery Series I, and Range Rover Classic, we recommend the N115 front shocks and N44 rear shocks. The reason for the N115 front shock and N44 rear shock is that they have slightly firmer valving than the N45F (medium front), N46 (medium rear), and N27 (soft rear) shocks, which are more suitable to the heavy loads that expedition vehicles must bear. However, installing N115 and N44 shocks on even the lightest Defender 90 will not give a harsh ride. As a comparison, the N115 and N44 shocks are considerably softer than the Bilstein shocks favored by so many Land Rover owners. If you have ever compared the valving on the Old Man Emu and Bilstein shocks, you will know that Bilstein shocks are considerably stiffer than the the N115 and N44 shocks. The N115 shocks are very close to the N45F shocks in terms of valving firmness. Similarly, the N44 shocks are close enough to the N46 and N27 that it is very difficult to tell the difference between the various Old Man Emu rear shocks. "

It sounds to me that they are about the same firmness, just wouldn't want a winch up front I imagine. More opinions please |

Robert Sublett (Rubisco98)

| | Posted on Tuesday, July 23, 2002 - 10:38 pm: |

|

Oh, and didn't mention in the first post that I had asked for HD all the way around.. Later.. RS |

Robert Sublett (Rubisco98)

| | Posted on Wednesday, July 24, 2002 - 08:33 am: |

|

{{{bump}}} |

Kyle

| | Posted on Wednesday, July 24, 2002 - 11:10 am: |

|

Hmmm , so let me get this straight. You are using EE's site to get your info to order from Nathan and then complaining about Nathan ?? THen going back to EE's site to further complain ? I dont think that does either of them any justice.

Kyle |

Dee

| | Posted on Wednesday, July 24, 2002 - 02:03 pm: |

|

I left this one alone last round but you picked my brain for several emails then went to Nathan

Good you bought from Nathan then talk to him about your product concerns or call ARB directly they have been very helpful in the past,

If you don't want to buy from John or Ho don't waste there time or resources after the purchase. I am not trying to speak for John or Ho but they have a considerable amount of time and effort keeping there site full of information and for the few dollars difference in prices to use there info and go some place else is wrong, Being I know all parties concerned John is great resource for ARB products even better than me, LOL he likes the stuff...

IMO opinion Bilstein's shocks are a far superior product than OME but that's another story, and you can buy the 6100 series custom valve if the ride on the 5100 are too harsh, Also you can get the 7100 series and valve yourself.

To paraphrase what Kyle posted before don't burn the candle at both ends you might get burned in the end |

Robert Sublett (Rubisco98)

| | Posted on Wednesday, July 24, 2002 - 03:35 pm: |

|

Kyle, I'm not complaining one bit whatsoever about Nathan. I think he is a great guy. I have ordered only once from EE and thought that they were great. I was going to order my steering stabilizer from EE within the next week or so. I thought that I needed the N115's. It was too late last night to call Nathan so I posted here hoping to get some thoughts on the matter. And Dee, I thought that you and Nathan were partners in biz. Is that not correct? In addition, Kyle, how was that complaining about EE, I don't see it as a complaint whatsoever either. I just wanted some galldarned info and opinions but once again I've offended everyone. Sheesh! I'm all about love man, no complaints to anyone at EE or Nathan. |

Moe (Moe)

| | Posted on Wednesday, July 24, 2002 - 04:48 pm: |

|

This is some hilarious shit. Damn, where would one go to complain about the grief one recieved from Dweb

Robert, just throw that spring package on quit worrying. There are plenty of people riding around very happy with that spring and shock combo. |

Dee

| | Posted on Wednesday, July 24, 2002 - 05:35 pm: |

|

Got to Pirate 4X4 to complain about dweb, LOL

And Robert I am no longer involved with Discount Rovers... |

Dee

| | Posted on Wednesday, July 24, 2002 - 05:38 pm: |

|

Got to Pirate 4X4 to complain about dweb, LOL

And Robert I am no longer involved with Discount Rovers... |

Robert Sublett (Rubisco98)

| | Posted on Wednesday, July 24, 2002 - 07:54 pm: |

|

I wish everyone would drink a happy shake and just chill out I quit for now.. but will be back in a week or so to piss Kyle and others off.. LOL (never thought I'd use the LOL since I've not done it yet with many years on the internet...but there ya go) Peace to everyone.. Robert Sublett I quit for now.. but will be back in a week or so to piss Kyle and others off.. LOL (never thought I'd use the LOL since I've not done it yet with many years on the internet...but there ya go) Peace to everyone.. Robert Sublett |

Chris (C_M_Sharpe)

| | Posted on Wednesday, July 24, 2002 - 08:23 pm: |

|

Dee,

Why do you think the bilsteins are a "far superior product" than the ome's? Not arguing, just curious. Would you go with LR HD springs or OME with your bilsteins.

thanks |

Kyle

| | Posted on Wednesday, July 24, 2002 - 08:24 pm: |

|

Kyle |

Dee

| | Posted on Thursday, July 25, 2002 - 06:26 pm: |

|

Chris,

Looks like the Lion above is waiting to pounce on me for this one.

I don't Like OME products to me there the same other makes such as Rancho, The OME shocks are decent but nothing to rave about. The MTR's seem a bit better and is a close third choice for me, as with all the shock options any shock is an improvement over the woodheads even Ranchos and like most you have to balance between budget and wants.

My main dislike with OME are there springs, the HD springs give a harsh ride (( Yes I had a Bull Bar)) the MD are not bad but not much lift so you have to then add perch spacers, why not get a spring to do the lift. Also the steel used is poor quality. why else would a 4k Lb vehicle get a 1/2" sag in 6 month's.. My rear right is almost 1" shorter than when the springs were new. I am getting tires of swapping left to right. There fix is to put Polly spacers to lift the springs back up, now at 1/3 the cost of a new spring why bother.

Also the finish applied is piss poor mine were solid rust in 3 months. If I wanted a rusted trail beater I would not care I don't like rust.

Springs that seem to have a good rep are John at RTE and Scorpion Racing in the UK, Scorpions products look good but I don't have a warm fuzzy about there business practices.

My best advice is go to Bilstein and read up @ http://www.bilstein.com/ read the data. Look who they supply shocks to, most of the major automakers use them, also who is out there in force on race day.

For me I go with what works, I have always had great luck with there products and received excellent customer service. A bonus for me is a main dist center is in San Diego.

Some dislike the ride of the Bilstein 5100 series claimed its to harsh, I guess that's a personal taste issue. The 6100 series can be valved to suit by the factory and the 7100 series by the user. Last week I found a similar shock that is less expensive alternative and comes in custom lengths, I will be looking into that in the coming weeks.

My main complaint with Bilstein is they wont sell to the small guys we have to go third party, that is why the prices go from 59 to 98 for the 5100 series. and gets really sick in the 7100 series

shop around the prices vary even worse than LR parts

FWIW Bilstein only makes steering stabilizers for Land Rovers and no other makes are available from them in the non OEM products |

Ho Chung (Ho)

| | Posted on Thursday, July 25, 2002 - 06:30 pm: |

|

interesting.  |

Kyle

| | Posted on Thursday, July 25, 2002 - 06:59 pm: |

|

Very......

Kyle |

Ho Chung (Ho)

| | Posted on Thursday, July 25, 2002 - 07:23 pm: |

|

kyle, you think so too? LOL |

Eric N (Grnrvr)

| | Posted on Thursday, July 25, 2002 - 07:24 pm: |

|

Uh Oh, Dee Look out!!!!

|

Blue (Bluegill)

| | Posted on Thursday, July 25, 2002 - 07:55 pm: |

|

|

Dee

| | Posted on Thursday, July 25, 2002 - 08:21 pm: |

|

Oh I knew i would get eaten up on this one, Flame away. OK OME are great and Rancho Rules |

Kyle

| | Posted on Thursday, July 25, 2002 - 08:26 pm: |

|

I am holding my tongue...... Its hard , but I am... And it aint about sucking or being great. Its about the lesser of the evils. So far they all suck ..

Kyle |

Paul D. Morgan (V22guy)

| | Posted on Thursday, July 25, 2002 - 08:29 pm: |

|

Rancho?

Don't get Greg Parrish started! HAHAHA |

Ho Chung (Ho)

| | Posted on Thursday, July 25, 2002 - 08:30 pm: |

|

kyle, hold it tight. LOL

i am still trying to figure out a gentle way of doing things.  |

Kyle

| | Posted on Thursday, July 25, 2002 - 09:07 pm: |

|

Well , lets put it this way. When you consider that a spring from the factory lasts a good 100K before its shot to shit and its no where near as stiff so it gets cycled more. What other spring maker is really "great" ?? I havnt seen one yet that lasts that damn long. Some last longer then others but none last that long...

Kyle |

Rob Davison (Pokerob)

| | Posted on Friday, July 26, 2002 - 09:01 am: |

|

my disco was sagged when i bought it at 9,000 miles on it and 2 years old, Before anymod's.

i don't know a truck out there with 100,000 miles that doesnt look all saggy

rd |

Kyle

| | Posted on Friday, July 26, 2002 - 09:50 am: |

|

"Look all saggy" ?? Yeah , they do look saggy because you are so used to being around lifted trucks. If yours was that saggy with the stockers you would have been able to run that ARB on there with the stock springs and get away with it...

Kyle |

Chris (C_M_Sharpe)

| | Posted on Friday, July 26, 2002 - 11:21 am: |

|

Dee,

Thanks for the input. Kyle and Ho, do you 2 have any specific comments (although I did like the picture of the white) regarding springs/shocks selection?

thx

cs |

kyle

| | Posted on Friday, July 26, 2002 - 12:21 pm: |

|

Chris , I will let you know when I find a spring that holds up over time..... Also , please take into consideration that Ho and I both run heavy. I run with probably round 800 LBS in the truck (250 of that being on the roof) and this is hard on springs off road. So our comentary might be a bit tainted.. Although , my view is that these springs were made for exactly what we are doing and they are indeed sagging. Ho and I were talking about it on the phone last night and there are quite a few OME trucks that we know of that have been running the same springs for quite a few years without issue. My truck is just no one of them... I will say however that the OME have been the longest to last on mine so far. And I havnt had a moments problem out of my front Rovertym springs....

Kyle |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 12:27 pm: |

|

I'm in Roberto's camp as far as stock LR suspension is concerned. At 60k my springs were sagging like Rosie O's ass and my shocks were absolute crap. Like drivin a big peanut butter sandwich. My OME HD is holding up well, but that damn "engineered lean" is ridiculous. Wish I had picked up a matched spring set from EE....... |

kyle

| | Posted on Friday, July 26, 2002 - 12:42 pm: |

|

How many miles you got on the OME ??

Kyle |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 12:44 pm: |

|

only 25 or so |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 12:45 pm: |

|

25k

and yeah yeah yeah I'll get back to you in 35k |

Kyle

| | Posted on Friday, July 26, 2002 - 12:46 pm: |

|

And put something in that bitch.... would ya ? Tat ARB compressor dont weight that much... And put something in that bitch.... would ya ? Tat ARB compressor dont weight that much...

Kyle |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 12:50 pm: |

|

I'm ready to drop a couple 45lb plates in the back to settle the rotobitch down a bit  |

Kyle

| | Posted on Friday, July 26, 2002 - 01:07 pm: |

|

Poor Roboflex........................

Kyle |

Eric N (Grnrvr)

| | Posted on Friday, July 26, 2002 - 01:11 pm: |

|

Blue, why not just get a new rear shaft/flange and be done with it and do away with the Rotoflex all together? |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 01:16 pm: |

|

it's on the list...somewhere between new rear window seals, adjusting door latch, new rear bearings, new oilpan seal, and new front bumper

seriously, has anyone ever made up their own flange to adapt the rotoflex-ready 3-bolt pinion flange to a standard 4-bolt u-jointed driveshaft. Balancing issues aside, what are other considerations? My rear diff is fine, and I don't really feel like tearing into it just to replace pinion flange. |

p m

| | Posted on Friday, July 26, 2002 - 01:18 pm: |

|

Kyle, my rear 762s sagged about 3/4" in a year and a half, I put maybe 50kmi on them. I like a sagged spring + spacer better than a brand new stiff spring, so they are there to stay. But i didn't expect them to sag so quickly.

too bad i don't remember which OME shocks I had. I liked the thick rods on them, but they were valved way too soft for a disco. If i knew that i'd have a rangie back then, i'd keep them. Stock-application bilsteins are on the harsh side off road, but excellent on the highway.

peter |

Ho Chung (Ho)

| | Posted on Friday, July 26, 2002 - 01:19 pm: |

|

springs: all springs sag. some more than others, some faster, and some a LOT faster than others.

shocks: no doubt bilstein quality is great (muskyman might say different  ). but if you can't get the right valving on the best quality shock, what good does it do? and please dont' compare OME shocks to ranchos. ). but if you can't get the right valving on the best quality shock, what good does it do? and please dont' compare OME shocks to ranchos.  |

Eric N (Grnrvr)

| | Posted on Friday, July 26, 2002 - 01:22 pm: |

|

You might have to have a custom length drive shaft made that would be shorter to make up for the difference in the rotoflex flange length and the adapter thickness.. I'm only guessing on this but, I think the rotoflex flange is actually longer then the non-rotoflex flange.. I don't have a rotoflex so I don't know for sure. |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 01:35 pm: |

|

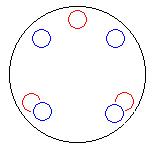

replacing rear driveshaft is a foregone conclusion. I'm just thinking of fabbing an adapter/spacer to mate the new u-jointed driveshaft end to the three-pronged pinion flange presently in-place:

|

John

| | Posted on Friday, July 26, 2002 - 01:37 pm: |

|

What do we want from springs....we do away with the stockers because we want to add winches, bumpers, sliders, etc just to go wheeling and add larger tires.The after market springs are made to handle the added static weight but strike a fine line to also try to offer a smoothe road ride that we demand in a spring. In wheeling, we go to Moab,Tenn, Ga,PA, etc,in our heavier after market trucks ,add 800 or so lbs in gear, gas, water, sand ladders, etc. all the stuff we feel we need to take along....then we get there and articulate, stuff, drop off ledges, climb obsticles, etc. The dynamic loading on springs is really tremendous when we drop off a ledge with 400 lbs in the back of our 5,000 Disco. We can at very least double the weight on a spring rating dropping off a ledge, or stuff a tire completely by articulation. Its really a cache 22 with the way some of us load up our truck then go wheeling on a weekend, but at the same time wanting a nice, smoothe ride around town all week. I am beginning to think everyone needs 2 pairs of rear springs to swap out for the weekend stuff to carry the dynamic weights we throw on a spring when we go wheeling. A spring designed to handle a 300 lb rate just cant stand up long term to the dynamic loading we put on them while aggressively wheeling with trucks carrying around 400/800 lbs of gear. |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 01:39 pm: |

|

how often do you guys swap out your bedsprings? LOL  a spring isn't a permanent item. a spring isn't a permanent item. |

John

| | Posted on Friday, July 26, 2002 - 01:46 pm: |

|

You cant make an adapter from a 3 bolt mount to a 4 bolt mount because you cant balance it as you end up with a 7 bolt mount non equispaced. |

Rob Davison (Pokerob)

| | Posted on Friday, July 26, 2002 - 01:52 pm: |

|

i think as set of helper air bags , if you could find a quality industrial strentgh set would be awesome for a disco. OR just let my bodge do the work

got bodge envy? hehehe

rd |

Ho Chung (Ho)

| | Posted on Friday, July 26, 2002 - 01:57 pm: |

|

hey john,

hope you are recovering well. when you coming to moab for some fun?

now, you can't just say catch 22 and leave it at that. somethings can be improved at cost of less important things.

the rear OME HDs i sent kyle are still doing pretty good aside from all the shit he carries PLUS the ledges and drop offs. so there's not really a need for 2 sets...

unless, of course, we talking slinky again.  |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 02:02 pm: |

|

yeah, I knew that balancing would be an issue....

if you could selectively locate 7 bolt holes @ 51.4 degree increments, it could theoretically be done, but the bolt-hole spacing is already predetermined by the existing flange and the shaft end.

how about customizing driveshaft to fit the custom adapter? LOL - talk about backwards engineering...the adapter needs an adapter |

Kyle

| | Posted on Friday, July 26, 2002 - 02:03 pm: |

|

Yeah , they aint dead but they also havnt really been anywhere yet... I am spring skiddish now. That freaking dual rate crap was supposed to stop the need for having two springs but Your ass is dragging the ground before that second rate starts doing its thing. I would estimate that you have to drop a good 1 1/2" in the ass before it stabilizes and I hate that shit. That makes stopping vibes harder and just generally makes it a pita to setup. Now the damn Boge....... please Rob , dont get me started again.....

Kyle |

p m

| | Posted on Friday, July 26, 2002 - 02:04 pm: |

|

John,

not to say anything about the idea of an adapter itself, but it seems to me to be no problem to balance it.

any number of equally spaced holes makes for a perfect balance. now, you have a perfectly balanced spacer with 3 holes, and drill 4 more equally spaced holes, in a way that no holes overlap or are shared between the two patterns. it will not introduce any imbalance.

peter |

p m

| | Posted on Friday, July 26, 2002 - 02:05 pm: |

|

Kyle, what's up with Boge?

peter |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 02:10 pm: |

|

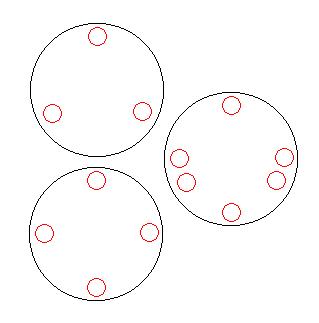

Peter,

on a piece of paper, draw two circles.

equally space 3 holes in one circle,

equally space 4 holes in the other.

now superimpose one cirlce over the other.

what do you have? |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 02:18 pm: |

|

|

Kyle

| | Posted on Friday, July 26, 2002 - 02:19 pm: |

|

A cluster fuck....

Kyle |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 02:24 pm: |

|

|

Paul T. Schram (Paulschram)

| | Posted on Friday, July 26, 2002 - 02:48 pm: |

|

Damn Blue, it took me a long time to draw those circles with a crayon and you probably burned that one off in a few minutes.

I too considered an adapter flange and quickly gave up on the idea, although, I'm now working on making a roto-flex centering pin puller so I can go universal in the back. I just don't like the thought of bothering with pinion preload if I'm not going to add a locker at the same time.

Has anybody successfully removed the roto-flex and set the pinion preload without pulling the third member? The last time (also the first time) I tried to swap a pinion flange without spending the time to do it right, I took eight teeth off of the ring gear. AB sells the kit. Has anybody bought one? I wonder what their instructions are for pinion bearing loading.

Paul |

John

| | Posted on Friday, July 26, 2002 - 02:55 pm: |

|

4 holes at 120 deg, 3 holes at 120 deg...you cannot make them share a commom radial center angular dimension of 51.428571428571 to infinity deg. for balance.

Ho, I am doing great thanks...being cautious but bushy tailed and eager as always. |

John

| | Posted on Friday, July 26, 2002 - 03:03 pm: |

|

Good idea on the hole pattern, but still cant balance that pattern, maybe too small to worry about, but thinking anyway is good, I wonder if the bolt dia's are the same on the 3 hole and 4 hole pattern? |

Kyle

| | Posted on Friday, July 26, 2002 - 03:17 pm: |

|

Well , isnt it a bit more complicated then that John ? You are looking at it at the most basic mechanical level and you are right ofcourse. Although , it can be balanced for feed back. In other words , you might not feel the vibe it causes but its still there... like a bomb..

Kyle |

Kyle

| | Posted on Friday, July 26, 2002 - 03:20 pm: |

|

oops , the reason I posted that last one is so that when people bail in saying "I have done that and I dont have any vibes at all" . You might not feel them but the equipment still does...

Kyle |

Paul T. Schram (Paulschram)

| | Posted on Friday, July 26, 2002 - 03:46 pm: |

|

OK Guys, I'm not wanting to argue with you, merely educate myself.

Why can't we add/remove metal to the unbalanced side to compensate for the material removed to allow for the bolt holes and for the mass of the bolts themselves? If we take Blue's pretty picture and drill and tap blind holes from opposite sides, we would cure the physical interference issues, but we would have a serious mismatch of masses around the axis. Could we then drill holes and fill them with Mallory metal (is that right, the stuff they add to crankshafts to balance?).

Are we looking to maintain a consistent density of material throughout 360'? I am painfully ignorant of the nuances of balancing such rotating parts,beyond the knowledge that when you have inconsistent densities, things tend to throb, or worse.

This seems reminiscent of the early Buick V-6s that had the funky crankshaft offsets to allow for balancing.

Remember I've already said I'm not oging to try to make an adapter, but will swap to universal someday after I win the lottery.

Of course, this is all academic, especially as cheap as the flanges and other parts are!

Glad you're feeling better John, my springs are holding up well and it's almost time for the front ones.

Paul |

Rob Davison (Pokerob)

| | Posted on Friday, July 26, 2002 - 03:47 pm: |

|

the OME SHD i had in the back of my disco. after the initial sag weere doing fine, even out west loaded up and you boys know i had some weight out there,. my problom was a complete lack of balance to my flex...

kyle has been complaining of the feel of his current setup so he's just saying that to argue.

i'm sticking with the industrial airbag conversion or boge type thing. |

Kyle

| | Posted on Friday, July 26, 2002 - 03:53 pm: |

|

You truck didnt get enough action to Sag Roberto....lol Kinda like mine right now. Freaking comuter car..

Kyle |

John

| | Posted on Friday, July 26, 2002 - 03:55 pm: |

|

Balancing that pattern is possible for a certain speed(rev) but you can only truly balance it for that one speed. So the time bomb is there.... If the bolt circles are the same its worth a try if you choose to do it. If the bolt patterns are different, then its more complicated. Seems like a good idea to use the right pinion flange and be done with it. |

Rob Davison (Pokerob)

| | Posted on Friday, July 26, 2002 - 04:01 pm: |

|

it got enough kyle, you are now wanting a spring for .001% of the owners. my truck had more than it's average share of action. true i didn't beat it, but i would twist it up all the time.

the expense to design a spring of such high metallurgical properties to do what you want is getting into nasa type testing and development.

i suppose you'll want it to work equally well at -40 deg in canada and 120 in the desert (plus engine heat)

rd |

Kyle

| | Posted on Friday, July 26, 2002 - 04:04 pm: |

|

Well ofcourse......

Kyle |

Rob Davison (Pokerob)

| | Posted on Friday, July 26, 2002 - 04:05 pm: |

|

ok

here is an idea, make the flang with a 1" deep groove around the OD, pour in some equal and then press a sleeve over the groove to seal it in

rd |

Kyle

| | Posted on Friday, July 26, 2002 - 04:11 pm: |

|

Just take the flange off and send it to me. Then buy a flange for a U joint and install it..... Done...

Kyle |

p m

| | Posted on Friday, July 26, 2002 - 04:36 pm: |

|

Blue,

have you read my post? here's a quote for you:

in a way that no holes overlap or are shared between the two patterns. it will not introduce any imbalance.

peter |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 04:48 pm: |

|

ok Kyle, you got it

sure it can be done, and it can eventually be seemingly balanced, but that's a severe case of over-engineering. Most logical option is "use the right pinion flange and be done with it."

reminds me of a book I read awhile back about the space program. Apollo engineers are piecing together circuit boards for the spacecraft. They've got stacked boards, and one is sagging and contacting the board below it, so they grab a brass doorknob and shove it in there to prop it up. When they're done, they send it all to be finished & fabbed. They get a bunch of finished units back, all complete with a perfectly milled block of brass with the exact specs of the original doorknob. |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 04:49 pm: |

|

OK, Peter, try rotating one of the cirlces and then superimposing in a way that makes sense..... |

p m

| | Posted on Friday, July 26, 2002 - 04:57 pm: |

|

shut up BLue, it's not your day.

just draw it for yourself, it'll become clear.

out of curiosity, i just did it in SolidWorks, and checked out the c.g.

no problemo.

peter |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 06:35 pm: |

|

OK fucker, i'll break out the crayolas again

and waddya tellin me to shuddup for? I want this to work! |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 06:45 pm: |

|

|

p m

| | Posted on Friday, July 26, 2002 - 06:55 pm: |

|

something tells me the holes need not to be this big (compared to the whole thing). just looked at the old roto in my garage. besides, there's a fat chance that the 4 bolt pattern is on the smaller bolt circle.

peter |

Kyle

| | Posted on Friday, July 26, 2002 - 06:59 pm: |

|

MAn , you coulda changed the damn flange with less effort then you have spent already.

kyle |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 07:01 pm: |

|

still man, you're talkin 3 @ 120 deg spacing vs. 4 @ 90 degree spacing.

Unless you totally reapproach with 7 @ 51.4xxxxxxx, it ain't gonna fly. And if you totally reapproach, you're talkin brass doorknobs. |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 07:01 pm: |

|

LOL |

Blue (Bluegill)

| | Posted on Friday, July 26, 2002 - 07:15 pm: |

|

this qualifies as extreme cyberwheelin

|

p m

| | Posted on Friday, July 26, 2002 - 08:16 pm: |

|

BLue,

you could have swapped the fucker for a regular yoke in the time you spend putting my truck in the scenic environment

OTOH, i could have downed two coronas instead of typing this...

peter |

Curtis N (Curtis)

| | Posted on Saturday, July 27, 2002 - 01:56 am: |

|

Blue,

It seems that the flaw in your drawings is that you are trying to share a common hole in the combo of bolt patterns. I believe that if you rotate either of the bolt patterns in the combo 60 deg. you will have the result you are looking for. I do not have the time to put together the graphic right now, but it sounds right.

Curtis |

John

| | Posted on Saturday, July 27, 2002 - 08:51 am: |

|

The 4 bolt pattern is really a rectangular pattern(2 3/8" x 2 1/8") so the "fix" gets tougher as it isnt a 90 degree spacing. Lay that out and ponder a solution. |

Rob Davison (Pokerob)

| | Posted on Saturday, July 27, 2002 - 10:47 am: |

|

i cant believe you guys are having this much trouble figuring out if you can get some holes to line up.. hehe it either does or doesn't. ya'll got some stephen hawkin readin' half-spin quirk theory going on here and it 's blowin' my mind on a saturday morning.

rd |

John

| | Posted on Saturday, July 27, 2002 - 11:24 am: |

|

Havent you seen sillier threads go for weeks?

This one is "something to do in the spare time" thread |

Kyle

| | Posted on Saturday, July 27, 2002 - 09:16 pm: |

|

Well it started out about springs so lets get back to em... boing boing boing........

Kyle |

Robert Sublett (Rubisco98)

| | Posted on Saturday, July 27, 2002 - 10:57 pm: |

|

A note to Kyle...

I installed my springs/shocks today with your help from the tech section. Didn't go about it exactly the same way but it would have been a PITA without your assistance. Also used your method for the rear fender relocation and stuck some 235/85 MT's under there. Looks much better and I cannot believe the ride. Other than sitting a bit taller and hearing my tires on the interstate, it is so much better than it was 24 hours ago. A special thank you to Kyle and Discoweb for great advice and for being such a great resource. Hope you are having a great weekend.. Thanks again.. Robert Sublett |

Curtis N (Curtis)

| | Posted on Saturday, July 27, 2002 - 10:57 pm: |

|

To hell with springs...too boring. Lets get back to holes. The point I was making above us that you do not want ANY holes to line up

Curtis |