Not sure you need the long intake runners when you have a pressurized intake charge. Also Whipple or Ken Bell superchargers are more efficient at lower rpm’s. That’s my thoughts on the matter.No turbos on this one; but I am very much looking at a screw or a roots. I understand how boost works... There is very little exploration in that. The stroke and other elements are very interesting to me; yeah, a billet crank is not in the cards; I will be saying this a million friggin times: this is to explore the extents of the what is possible, or at least semi-rationally plausible.

I will likely end up with a 4.6 crank and an M122 (or hopefully a screw blower), along with a home built (very long runner) custom intake and custom headers. (I know how to tig weld... my Dads' got an awesome set of tools!)

Alfred's Holy Grail - Low RPM High Torque RV8

- Thread starter DiscoClay

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

That reminds me a bit of this -I will be saying this a million friggin times: this is to explore the extents of the what is possible, or at least semi-rationally plausible.

kid4lyf said:Please don't jump in with a bunch of second hand opinions, I'm looking for actual first hand experience.

Yeah...well... At this point; rational, experiential guesswork is welcomed ;-P

I am working on a new gig but I need to get this 4.0 disassembled so that I can make my own measurements. I am digging to see if I can make a SBB350 crank clear the cam and block. I can mod the pan and notch the sleeves (SBB350 = 3.85" / 97.79mm). I may need to call D&D but I didn't get happy vibes from him (he's prol done with tire kicking callers .

.

Has anyone explored doing sleeves larger than 96mm?

I am working on a new gig but I need to get this 4.0 disassembled so that I can make my own measurements. I am digging to see if I can make a SBB350 crank clear the cam and block. I can mod the pan and notch the sleeves (SBB350 = 3.85" / 97.79mm). I may need to call D&D but I didn't get happy vibes from him (he's prol done with tire kicking callers

Has anyone explored doing sleeves larger than 96mm?

Boost does nothing to the runner length equationNot sure you need the long intake runners when you have a pressurized intake charge. Also Whipple or Ken Bell superchargers are more efficient at lower rpm’s. That’s my thoughts on the matter.

While Richard has a TONNE of vids about the boost/manifold stuff. This is not the main one I am thinking of, but he talks about it right here:

Last edited:

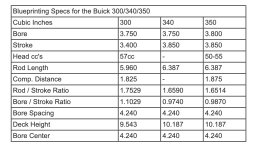

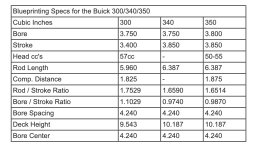

Buick Wildcat (300 and 340) specs, for the mildly curious:

credit to the teambuick boys: https://www.teambuick.com/reference/300-340_engine_specs.php

credit to the teambuick boys: https://www.teambuick.com/reference/300-340_engine_specs.php

Last edited:

I should drop some 4/4.6 specs in here.

The 3.5/3.9/4/4.6 deck height is 8.960" (your results may vary). This being only 0.060" (60 thou) shorter than sbc means small block chevy rods are a real option. Also, custom (low compression height) pistons can be made from SBC forgings for (not cheap but not batshitcraycray) prices.

The deck heights:

Rover V8: 8.960" (227.58mm)

SBB 300: 9.543" (242.39mm)

SBB 340: 10.187" (258.75mm)

SBB 350: 10.187" (258.75mm)

So.. this is why I am thinking "if I can make the crank throws clear the block & cam, then mod the pan...and make deck spacers (~1.00"/25.4mm or more) and bore for 96.52mm extended sleeves... That gives 350 cubes / 5.7L of under-square displacement. With a very mild cam (VERY necessary in this application) and tack on about 3psi of boost above ~1800rpm and p00f [shift gently] you've got about 400ftlb of torque in the ~2800rpm range (~200lb-ft@ ~1400rpm)

So.. IF all that worked (lots of ifs) then a fairly short rod ratio is going to be best for low RPM torque. This means a 1.25-inch deck spacer would be handy (consider a sbb350, with it's ~10.2" deck, ~6.4" rod, and 3.85" stroke gives a 1.65:1 rod/stroke ratio). The drawback is that increased side load on the cylinder. So.. maybe as low as a 1 inch deck plate with a shorter rod (sbc 6.2, etc) and a tight compression height.

(for more on the affects of rod ratio: https://www.hpacademy.com/technical-articles/rod-to-stroke-ratio-explained/ )

Here are the SBB 350 block and crank specs (again, thanks go to TeamBuick: https://www.teambuick.com/reference/350_engine_specs.php):

The 3.5/3.9/4/4.6 deck height is 8.960" (your results may vary). This being only 0.060" (60 thou) shorter than sbc means small block chevy rods are a real option. Also, custom (low compression height) pistons can be made from SBC forgings for (not cheap but not batshitcraycray) prices.

The deck heights:

Rover V8: 8.960" (227.58mm)

SBB 300: 9.543" (242.39mm)

SBB 340: 10.187" (258.75mm)

SBB 350: 10.187" (258.75mm)

So.. this is why I am thinking "if I can make the crank throws clear the block & cam, then mod the pan...and make deck spacers (~1.00"/25.4mm or more) and bore for 96.52mm extended sleeves... That gives 350 cubes / 5.7L of under-square displacement. With a very mild cam (VERY necessary in this application) and tack on about 3psi of boost above ~1800rpm and p00f [shift gently] you've got about 400ftlb of torque in the ~2800rpm range (~200lb-ft@ ~1400rpm)

So.. IF all that worked (lots of ifs) then a fairly short rod ratio is going to be best for low RPM torque. This means a 1.25-inch deck spacer would be handy (consider a sbb350, with it's ~10.2" deck, ~6.4" rod, and 3.85" stroke gives a 1.65:1 rod/stroke ratio). The drawback is that increased side load on the cylinder. So.. maybe as low as a 1 inch deck plate with a shorter rod (sbc 6.2, etc) and a tight compression height.

(for more on the affects of rod ratio: https://www.hpacademy.com/technical-articles/rod-to-stroke-ratio-explained/ )

Here are the SBB 350 block and crank specs (again, thanks go to TeamBuick: https://www.teambuick.com/reference/350_engine_specs.php):

Last edited:

I stumbled across a little snippet that indicates the stock deck RV8 (same deck as the sbb215) will *at least* support a 3.75" stroke:

https://www.leylandp76.com/technical/tech-headflow.html ...this is Dan Jones' EXCELLENT data dump on head flow.

That would give a 96mm sleeve (I hear this is the bleeding edge, and 94.75 is much safer) a 5.5L/337cu displacement.

https://www.leylandp76.com/technical/tech-headflow.html ...this is Dan Jones' EXCELLENT data dump on head flow.

That would give a 96mm sleeve (I hear this is the bleeding edge, and 94.75 is much safer) a 5.5L/337cu displacement.

That site has some great old info from ~18-20yr ago.

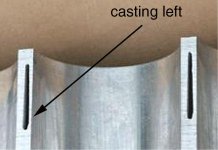

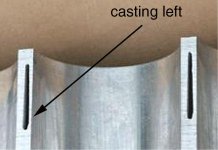

Check out this casting cross section that shows the danger of boring for 96mm liners as well as a clear shot of the crank - cam clearance consideration:

It seems the Darton MID solution might be a good fit for the RV8... And that would allow a 4.00" bore. Of course it's a $7500 experiment

Check out this casting cross section that shows the danger of boring for 96mm liners as well as a clear shot of the crank - cam clearance consideration:

It seems the Darton MID solution might be a good fit for the RV8... And that would allow a 4.00" bore. Of course it's a $7500 experiment

Last edited:

Maybe I'll weld up a 4.6 crank and stroke it, otherwise it's a bunch of cutting, grinding, and welding on a 340/350 crank or one of those unfinished Castings. I wonder if the rough castings will go out to 98mm? Doesn't look like it without using the Darton MID process.

Here is a rollup of the generic crank differences (NOT including snout & tail shaft differences, which are significant!):

[please let me know if this has errors and I will correct them]

Here is a rollup of the generic crank differences (NOT including snout & tail shaft differences, which are significant!):

[please let me know if this has errors and I will correct them]

Engine | STROKE | BORE | MAIN JOURNAL DIA. | ROD JOURNAL DIA. | Displacement |

| Buick 215 | 71mm / 2.80in | 88.9mm / 3.50in | 2.30 (2.2992)in / 58.42 (58.39968)mm | 2.00 | 3.528L / 215.3cu |

| ROVER 3.5 | 71mm / 2.80in | 88.9mm / 3.50in | 2.30 (2.2992)in / 58.42 (58.39968)mm | 2.00 | 3.528L / 215.3cu |

| ROVER 3.9 | 71mm / 2.80in | 94mm / 3.70in | 2.30 (2.2992)in / 58.42 (58.39968)mm | 2.00 | 3.946L / 240.8cu |

| ROVER 4.2 | 77mm / 3.03in | 94mm / 3.70in | 2.30 (2.2992)in / 58.42 (58.39968)mm | 2.00 | 4.275L / 260.9cu |

| ROVER 4.0 | 71mm / 2.80in | 94mm / 3.70in | 2.50 (2.4995)in / 63.5 (63.4873)mm | 2.1875 | 3.946L / 240.8cu |

| ROVER 4.6 | 82mm / 3.23in | 94mm / 3.70in | 2.50 (2.4995)in / 63.5 (63.4873)mm | 2.1875 | 4.552L / 277.8cu |

| BUICK 300 | 86.36mm / 3.4in | 95.25mm / 3.75in | 2.50 (2.4995)in / 63.5 (63.4873)mm | 2.00 | 4.923L / 300.41cu |

| BUICK 340 | 97.79mm / 3.85in | 95.25mm / 3.75in | 3.00 (2.9995)in / 76.2 (76.1873)mm | 2.00 | 5.575L / 340.2cu |

| BUICK 350 | 97.79mm / 3.85in | 96.52mm / 3.8in | 3.00 (2.9995)in / 76.2 (76.1873)mm | 2.00 | 5.724L / 349.31cu |

Last edited:

Those buick guys.. heh heh, Passing more info on here, to memorialize; Specifically: the rare-ish aftermarket cam grinds from the New World  Kenne-Bell cams for the 215/300/340/350 SBB: https://www.teambuick.com/reference/library/v8_cams_kenne-bell.php

Kenne-Bell cams for the 215/300/340/350 SBB: https://www.teambuick.com/reference/library/v8_cams_kenne-bell.php

I spoke with the guy that makes the cast stroker cranks; he confirmed that his crank's can be finished out to 98mm stroke. To clear this swing, at least one of the oil gallery casting areas needs to be ground down, which requires sleeving it; he said this was an easy and straightforward (and reliable) process. He said the rods need to be well thought out, of course (i.e.: $$$) for clearance. He build and ran a reliable 5.3L using 98mm of stroke with 94mm tophats in a crossbolted block.

Also, TAperformance, in Arizona, specializes in Buick speed parts and makes a custom Rover V8 aluminum head! It looks very interesting and is very expensive. They did some nice upgrades and it's worth drooling over. They also make roller cams, and sell them ground or blank: https://www.taperformance.com/proddetail.asp?prod=TA_2150

Also, TAperformance, in Arizona, specializes in Buick speed parts and makes a custom Rover V8 aluminum head! It looks very interesting and is very expensive. They did some nice upgrades and it's worth drooling over. They also make roller cams, and sell them ground or blank: https://www.taperformance.com/proddetail.asp?prod=TA_2150

Also, TAperformance, in Arizona, specializes in Buick speed parts and makes a custom Rover V8 aluminum head! It looks very interesting and is very expensive. They did some nice upgrades and it's worth drooling over. They also make roller cams, and sell them ground or blank: https://www.taperformance.com/proddetail.asp?prod=TA_2150

TA performance only makes a long nose billit not a gems bosch nose profile. I had to take their blank and have it custom profiled to run full roller in Annabelle. Calling 8 different machine shops to find one that would even look at it.

I was thinking about this yesterday as i was driving Annabelle to a car meet. I am glad i have a high rpm cam in it. and the real torque is around 3000-4000 rpm. R380 and 4.71 gears if the cam i had was running in the stock rpm range with low end torque would be atrocious. You really want a much higher rpm range with a manual transmission and big gearing. That said that low rpm torque would be great only if your running an automatic transmission. Also you probably want to think about torque converter strength and stall speeds.

Everyhting affects the next piece of the puzzle.

I don't know the actual lengths of the 3.9 and 4/4.6 cams. I will be using a '97 4.0 GEMS (NAS) as the basis for the build.TA performance only makes a long nose billit not a gems bosch nose profile. I had to take their blank and have it custom profiled to run full roller in Annabelle. Calling 8 different machine shops to find one that would even look at it.

**update** I spoke with Mike at TA and he indicated that he makes these cams and can accommodate ether/both

The lowest gears I've ran in a disco was 4.11's with 32" muds and a 4HP24 behind a Navistar Powerstroke HS2.8VNT (the modernized 300tdi)... It's low end torque was something to behold. From 0-20mph it surprised many folksI was thinking about this yesterday as i was driving Annabelle to a car meet. I am glad i have a high rpm cam in it. and the real torque is around 3000-4000 rpm. R380 and 4.71 gears if the cam i had was running in the stock rpm range with low end torque would be atrocious. You really want a much higher rpm range with a manual transmission and big gearing.

I'm running an R380 with stock gears and 32" tires. This puts Alfred at 2000rpm @60mph. I spend most of my time between 25mph and 70mph (with a upper bellcurve in the 35-55 range, which means 1500-2500 with occasional visits up to ~4K max.).That said that low rpm torque would be great only if your running an automatic transmission. Also you probably want to think about torque converter strength and stall speeds.

Everyhting affects the next piece of the puzzle.

Last edited:

I am homing in on the following:

I'd still love to do a stroker, just to see what can be done.. maybe when my *next* startup is successful...

- 4.6 crank

- Custom very-long runner intake (of my own design)

- M122 eaton or similary sized whipple/screw supercharger with intercooler

- Custom long tube 8-4-2-1 exhaust (of my own design); to maximize low RPM scavenge **AND** give a nice Euro~flat-crank exhaust note (ish).

- Lots of coils (8)

- A fully sequential injection ECU (very useful below 3000 rpm)

- Capacitive Discharge Ignition (very useful below 3500 rpm)

I'd still love to do a stroker, just to see what can be done.. maybe when my *next* startup is successful...

Depending upon how the intake comes out, I may make a few and see if anyone is willing to buy one or two. I may experiment with a non-blower version of the very-long-runner intake [heretofor known as the VLR intake or the VLRLR intake ;-P] as well. Not sure yet.

I really want to use a whipple/screw supercharger (quieter, more efficient) but I will probably end up with an M122.

The M122 will probably be the choice because it's large and cheap (compared to a screw). I am interested in low RPM power without a lot of noise. Not only is the blower quieter the slower you spin it (to a certain extent) but it's also more efficient (drag is based upon velocity).

Of course a screw blower would more easily make low rpm boost but I don't expect much of a difference.. and certainly not ~$2k-$3k worth of diff.

I really want to use a whipple/screw supercharger (quieter, more efficient) but I will probably end up with an M122.

The M122 will probably be the choice because it's large and cheap (compared to a screw). I am interested in low RPM power without a lot of noise. Not only is the blower quieter the slower you spin it (to a certain extent) but it's also more efficient (drag is based upon velocity).

Of course a screw blower would more easily make low rpm boost but I don't expect much of a difference.. and certainly not ~$2k-$3k worth of diff.

I have exhausted my maximalist stroker exploration:

It looks like I am going with a 4.6 build combined with an eaton m90 (or m112/122 based upon opportunity), and will be fabricating my own very-long-runner intake manifold (with water:air intercooler) and my own 8:4:2:1 headers~exhaust.

This will use a roller hydraulic cam based upon the TAperformance.com blank. Sorting out the rod-piston combo and deciding on the cam profile is still under study.

The cam will likely have very aggressive ramps with a tight LSA and very little overlap (aggressive ramps allow the tighter the Lobe Separation Angle, while also enhancing the strength of both the intake and exhaust pressure wave pulse intensity (which is easy with a high RPM engine but much softer at very low RPM).

I am looking at using custom pistons and customized rods. The main goal being to have as short a rod as possible (without undo sideloading) to maximize low RPM boost capability (speed up the piston near TDC reduces low-speed detonation, while short rods enhance torque). The compression hight will be addressed with custom pistons that are based upon an existing forging; a side benefit is the ability to use thinner, harder rings and gas ports.

It looks like I am going with a 4.6 build combined with an eaton m90 (or m112/122 based upon opportunity), and will be fabricating my own very-long-runner intake manifold (with water:air intercooler) and my own 8:4:2:1 headers~exhaust.

This will use a roller hydraulic cam based upon the TAperformance.com blank. Sorting out the rod-piston combo and deciding on the cam profile is still under study.

The cam will likely have very aggressive ramps with a tight LSA and very little overlap (aggressive ramps allow the tighter the Lobe Separation Angle, while also enhancing the strength of both the intake and exhaust pressure wave pulse intensity (which is easy with a high RPM engine but much softer at very low RPM).

I am looking at using custom pistons and customized rods. The main goal being to have as short a rod as possible (without undo sideloading) to maximize low RPM boost capability (speed up the piston near TDC reduces low-speed detonation, while short rods enhance torque). The compression hight will be addressed with custom pistons that are based upon an existing forging; a side benefit is the ability to use thinner, harder rings and gas ports.

Do you have any interest in making a 5.7L Rv8? my colleague has a RV8 block with I think a Buick 350 crank, top hat liners, ect. I don't know that he's trying to sell it, but he's spent a fortune on machine work for it. While we love the Rv8, he's moved onto the LS platform.

Would any of you be interested in a low-rpm torque 'performance kit'? I am NOT trying to sell them, this is more of a "if I go through all this and it actually makes a solid 4.6 based torque monster (a relative term here), then maybe I will try to sell a few (sets of parts) to spread the love. I really like the idea of sticking with the small V8 rather than going through the LS swap option (which is a "drop back and punt" move, imo... not that I don't like the LS; it's an AMAZING engine).

I am thinking that if I can manage to get this build dialed in, maybe I can make a few of them and sell them as kits of various stages.

stage 1: NA ultra-long runner intake & ultralong primary 8-4-2-1 exhaust (D1 to start but probably RRC and maaaaybe D2)

stage 2: M90/M112/M122/screw (not sure yet, but M90 is preferable for size and cost) with ULR-intake & ULP-exhaust

stage 3: stage 1 + hydraulic roller cam (HRC) based on the TA blank

stage 4: stage 2 + HRC

stage 5: stage 3 + TAperf heads

Stage 6: stage 4 + TAperf heads

I am exploring parametric intake designs (basically flat aluminum sheets cut and fit together to form the runners. It will be a *LOT* easier for me to build (just lots of TIG time) and while it won't handle much boost (not like a tubular intake will), it should be plenty strong enough for <10psi (ideally 5-7psi) and it would make mounting the supercharger a lot easier.

Basalt fiber is also an option, but I am not quite there with the mold/jig design.

Remember, the goal here is max and flat torque at low revs: 1500-4500 rpm. BALLPARK Goals are 300hp@4500rpm, 350lbft@2200rpm (crank). I don't know how short we can make the rods but any amount will help for low-rpm boost, especially in conjunction with the TAperf heads.

I am thinking that if I can manage to get this build dialed in, maybe I can make a few of them and sell them as kits of various stages.

stage 1: NA ultra-long runner intake & ultralong primary 8-4-2-1 exhaust (D1 to start but probably RRC and maaaaybe D2)

stage 2: M90/M112/M122/screw (not sure yet, but M90 is preferable for size and cost) with ULR-intake & ULP-exhaust

stage 3: stage 1 + hydraulic roller cam (HRC) based on the TA blank

stage 4: stage 2 + HRC

stage 5: stage 3 + TAperf heads

Stage 6: stage 4 + TAperf heads

I am exploring parametric intake designs (basically flat aluminum sheets cut and fit together to form the runners. It will be a *LOT* easier for me to build (just lots of TIG time) and while it won't handle much boost (not like a tubular intake will), it should be plenty strong enough for <10psi (ideally 5-7psi) and it would make mounting the supercharger a lot easier.

Basalt fiber is also an option, but I am not quite there with the mold/jig design.

Remember, the goal here is max and flat torque at low revs: 1500-4500 rpm. BALLPARK Goals are 300hp@4500rpm, 350lbft@2200rpm (crank). I don't know how short we can make the rods but any amount will help for low-rpm boost, especially in conjunction with the TAperf heads.

Last edited: