That's adjusted for engine output. I read that somewhere.. i will look for the link!Of course it isn't. It is rated at least that much times the first gear ratio (~2.5).

I'm pretty sure first gear on my R380 is ~3.69:1 ...so that makes 232lbft * 3.69 * 3.32:1 (low range) * 3.54 = ~10,000lb/ft torque... a smidge above 300

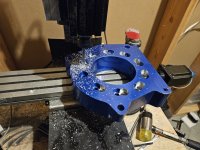

On a related note, have any of you used the ashcroft limited slip center diff? (https://ashcroft-transmissions.co.uk/product/ashcroft-lt230-atb-diff/). That said, you can order a brand new Ashcroft LT230 with 300M intermediate shaft, 300M output shaft, deep sump, and the LD center (diff-lock still works) for ~$2500 all in. THAT is tempting

I'm playing with the new grok3, so I asked it what it thought, here is what it spit out (your results *will* vary):

Further Digging on Torque Ratings (Converted)

R380 Torque Rating (NAS V8)

- Revised Estimate: ~380 Nm = 380 × 0.737562 = 280 lb-ft crank input capacity.

- Support:

- Ashcroft: Suggests stock capacity near 400 Nm (295 lb-ft) before upgrades. Ashcroft - R380.

- Syncro Gearboxes: Rates it at 380 Nm (280 lb-ft). Syncro Gearboxes - R380.

- Matches 3.9L V8’s 315 Nm (232 lb-ft) with margin.

LT230 Torque Rating (NAS V8)

- Revised Estimate:

- Continuous: ~550 Nm = 550 × 0.737562 = 406 lb-ft crank input capacity.

- Transient Peaks: ~1,200 Nm = 1,200 × 0.737562 = 885 lb-ft at the input.

- Support:

- Ashcroft: Implies ~500-600 Nm (369-443 lb-ft) stock limit. Ashcroft - LT230.

- Land Rover FAQ: ~400-450 lb-ft (542-610 Nm). Land Rover FAQ.

- Pirate 4x4: Survives ~1,750 Nm (1,290 lb-ft) R380 output in swaps. Pirate 4x4.

Summary in Both Units

- Engine: 315 Nm (232 lb-ft).

- R380 Capacity: ~380 Nm (280 lb-ft).

- 1st Gear Output: 1,163 Nm (858 lb-ft), with loss: 1,105 Nm (815 lb-ft).

- 5th Gear Output: 231 Nm (170 lb-ft), with loss: 219 Nm (162 lb-ft).

- LT230 Capacity: ~550 Nm (406 lb-ft) continuous, ~1,200 Nm (885 lb-ft) peak.

- 1st Low Output: 3,668 Nm (2,706 lb-ft), with loss: 3,485 Nm (2,570 lb-ft).

- 5th High Output: 265 Nm (196 lb-ft), with loss: 252 Nm (186 lb-ft).

- Wheel Torque:

- 1st Low: 12,336 Nm (9,098 lb-ft), with loss: 11,719 Nm (8,645 lb-ft).

- 5th High: 892 Nm (658 lb-ft), with loss: 848 Nm (625 lb-ft).

This covers the torque flow and ratings in both Nm and lb-ft, keeping the NAS D1’s drivetrain in focus. Let me know if you’d like a per-gear breakdown or more source hunting!