I think we have an english terminology difference here, below is what I was reading for that setting. We call these axle shafts and the book calls these drive shafts.

Refit (for the rear)

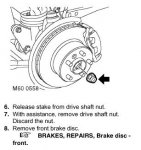

1. Clean drive shafts, wheel hubs and wheel hub locations in rear axle.

2. Using a suitable solvent, clean old RTV sealant from differential and axle mating faces.

3. Apply RTV sealant to differential or axle mating face.

4. Apply Loctite 243 to threads of differential securing bolts.

5. Fit differential to axle, fit bolts and tighten to 55 Nm (41 lbf.ft).

6. Clean pinion flange and centralising peg.

7. Using a tubular drift, fit centralising peg to pinion flange. Ensure that the large diameter part of the centralising peg is below pinion flange mounting surface.

8. Position propeller shaft and align reference marks.

9. Fit nuts and bolts securing flexible coupling to pinion flange and tighten to 76 Nm (56 lbf.ft)

10. Lubricate 2 new wheel hub 'O' rings with clean differential oil.

+CAPACITIES, FLUIDS AND LUBRICANTS, Lubrication. Install 'O' rings on wheel hubs.

11. Fit LH and RH drive shafts and wheel hubs to rear axle. Fit wheel hub bolts and tighten to 100 Nm (74 lbf.ft).

12. Connect each ABS sensor multiplug and secure harness to harness bracket and brake hose.

13. Fit LH and RH rear brake discs. +BRAKES, REPAIRS, Brake disc - rear.

14. Remove stand(s) and lower vehicle.

15. Fill differential with oil.

+MAINTENANCE, PROCEDURES,

Front and rear axle.

M51 0042B

This table is from the torque wrench settings:

Axles

TORQUE DESCRIPTION METRIC IMPERIAL

Differential to axle bolts 55 Nm (40 lbf.ft)

Hub to axle bolts 100 Nm (74 lbf.ft)

Pinion flange bolt 100 Nm (74 lbf.ft)

Drive shaft nut 490 Nm (360 lbf.ft)