Part 2: I’m Seeing Red.

After the trip to The Wilds one thing was apparent: This truck desperately needs a winch.

There are only a few options when it comes to mounting a winch to the front of a Disco 3.

1) That ridiculous contraption that Land Rover sells

2) Steel Winch Bumper

3) Hidden Winch Mount

At the time, I was not happy with any of the available bumpers on the market. Quite frankly, they stick out too far. The LR3 has a fantastic approach angle so why would you add 10” to it and take away such a great asset? That point being made, the choice was simple.

Hidden Winch Mount.

I chose to go with the Terrafirma Hidden Winch Tray for several reasons. First, their tray comes standard with oversized mounting hardware along with reinforced brackets that attach the tray to the frame. Second, with the TF tray, you can fit a plethora of winches to it. Third being the excellent price point it is offered at pretty much helped concrete the decision.

Of course going with the hidden design has its cons as well.

Where do you put the solenoid box if it is not integrated? Yes, you can extend the wires and move the box into the engine bay which isn’t a big deal, but it does add to the job. If the solenoid pack is integrated, then you will need to cut a hole big enough to put your hand through to plug in the controller.

How do you get it to free-spool? This is the worst part of any hidden winch tray. You can power the line out, but that takes forever, and if you’re taking on water then you don’t have time for that. You can clock the lever and get it into the best position, but you will still have to cut the bumper to allow for handle actuation.

I wanted to avoid the entire free-spool issue altogether, so I went with this bad boy.

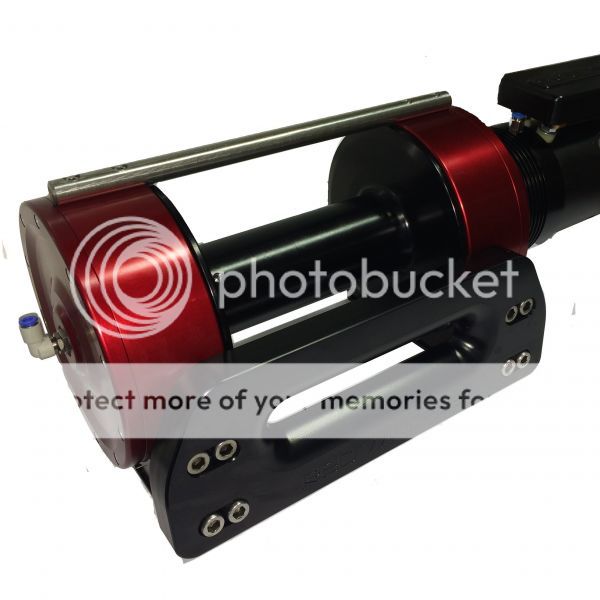

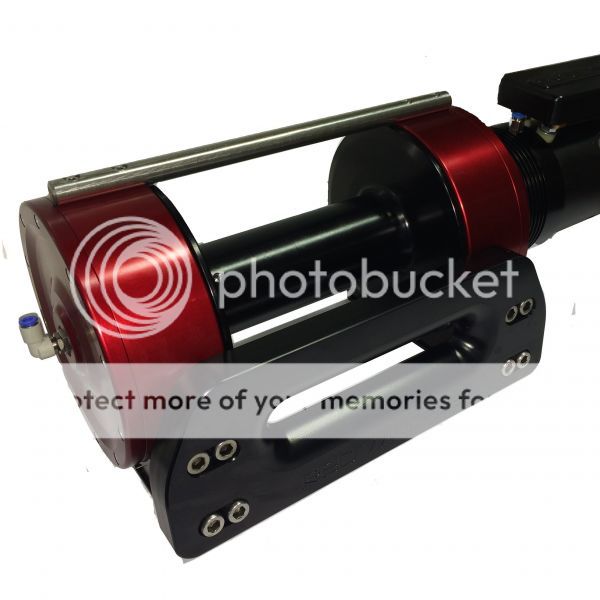

The Viper!

If you don’t know about these winches, please indulge me as I get on my soapbox and bend your ear for a minute.

Red Winch is quickly becoming the #1 name in Winch Challenge Events. If that’s not badass enough for you, these winches are also starting to pop-up on rigs being driven in the King of Hammers. It is understandable that you would not normally see a Red Winch on this caliber of truck, but our goal was to stuff one into the nose of an LR3 anyways.

The Viper, like all competition spec Red Winches, is CNC machined from aerospace aluminum. Even with its monster motor, it still weighs less than most 9k winches on the market today. Even with its lightweight body, the 71-pound Viper will still pull 100’ of line in just 55 seconds. For a reference point, the 89-pound Warn 9.5cti (which is a fantastic winch as well) pulls 47’ of line in 60 seconds. By my basic calculations, and I’m no mathematician, that is almost twice as fast. These features coupled with Red Winch’s military background make the Viper a tiny red Hulk!

All of those eye-popping features are great, but it is the air free-spool and brake system that I was most excited about. The air free-spool and brake system on the Viper have something that was previously unavailable on a winch of this size: To free-spool out, simply hit the switch.

Yep, that’s it. No need to jam your hand in a hole to move a lever. The brake system is also a real nice feature worth noting. What it does is stop the winch as soon as you let off the button. For example, if you are winching up a hill and start going off course, you let off the switch and you simply stop where you are. There is no run off or rolling backwards. It is amazing.

Now you know why I wanted to go with the Red Winch. But by now I’m sure you’re more interested in “the how”. The plan was simple: stuff this monster into the front of the Project LR3 and as Ron Burgundy would say “keep it classy”.

Here is how I did it. You can decide if it receives Ron’s stamp of approval or not.

Step 1 – Remove the lower protection plate and admire the buildup of mud from adventures past.

Step 2 – Remove grill, headlights and bumper cover.

Step 3 – Pull the air deflector out. The one bolt next to the radiator is a real PITA.

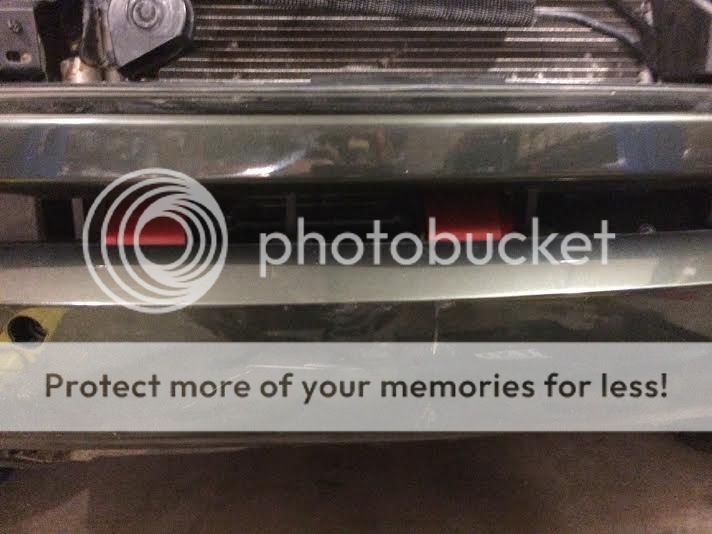

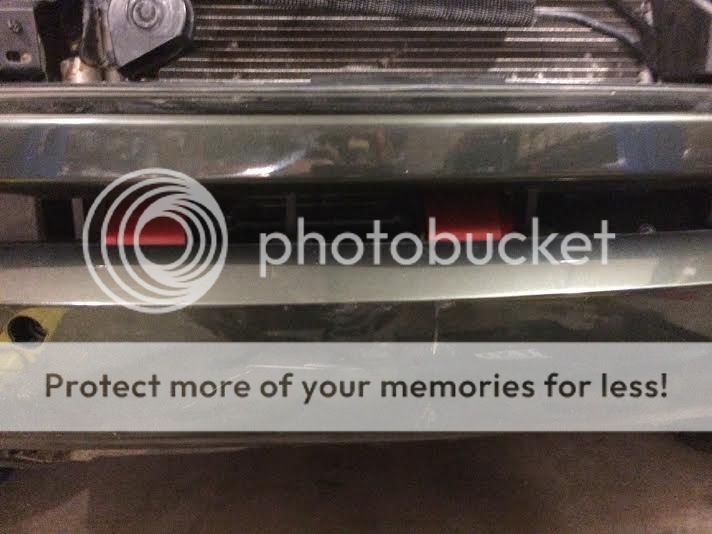

Step 4 – Do the NAS mod. The NAS V8 trucks have a condenser that interferes with the tray. It is a common issue with any hidden tray that we have ever come across. The first thing you need to do is remove the upper cross bar. I do not know why it is there.

Next, you need a simple notch for the condenser.

Test fit your cut out. I like to file down the edges to smooth and the hit the cutout with a shot of spray paint or cold galvanizing paint.

Step 5 – If you are putting in a standard winch, all you need to do is drop it in and wire it up.

The Viper is longer and thus offset due to the large motor, but it is not much taller than a standard size winch. This was an easy fix. All we needed to do was expand the fairlead opening on the front of the tray.

The upper tie-bar sticks off the top of the winch about a 1/2".

That ½” is just about all I needed to get the Viper to fit. To get the extra room needed, I simply removed the lower portion of the tiny upper-bumper cover support with a grinder. I have a sneaking suspicion that this truck is going to see Mr. Grinder again in the future.

Step 6 – With everything in place, the next thing to do is cut out the fairlead hole in the bumper cover.

Step 7 – Install the fairlead.

[/URL]