Lucky8’s Project Discovery 3

- Thread starter FIVESPDDISCO

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This truck has a major identity crisis going on.

I'm having an identity crisis too.....I cant decide if I like Widener's Seeing Red post or Shake It Off better....

.

King Shock are quickly becoming the #1 name in shocks. If that’s not badass enough for you, these shocks are also starting to pop-up on rigs being driven in the King of Hammers. It is understandable that you would not normally see a King Shock on this caliber of truck, but our goal was to stuff some into into the LR3 anyways.

Go big or go home, because you can.

Go big or go home, because you can.

I just ordered a set of those for the rear hatch on my lr3. I'll have to do a little fab work but it will be worth it.

Kings are so yesterday…ADS 5" 5 tube bypass shocks would work wonders…1" inch shaft when the thread goes gay

Are these something you'd normally see on this caliber of truck?

While our increased coating does provide a superior level of protection, dirty lines should still be gently washed with a mild soap and water to remove debris. Over time and use without cleaning, the dirt will act like sandpaper and start to degrade the coating, and eventually it can degrade the strength of the fibers.

Just a friendly reminder to have your winch rope dry cleaned.

Project LR3 update Rock'em Sock'em Robot

Armed with my new monster winch and gained confidence in the truck. I headed off to the conclave.

The conclave was held at The Cove in VA. Most of the trails I saw were hard packed dirt. Trails are tightly woven through the trees with many elevation changes. If you have a chance to attend an event here I would recommend it.

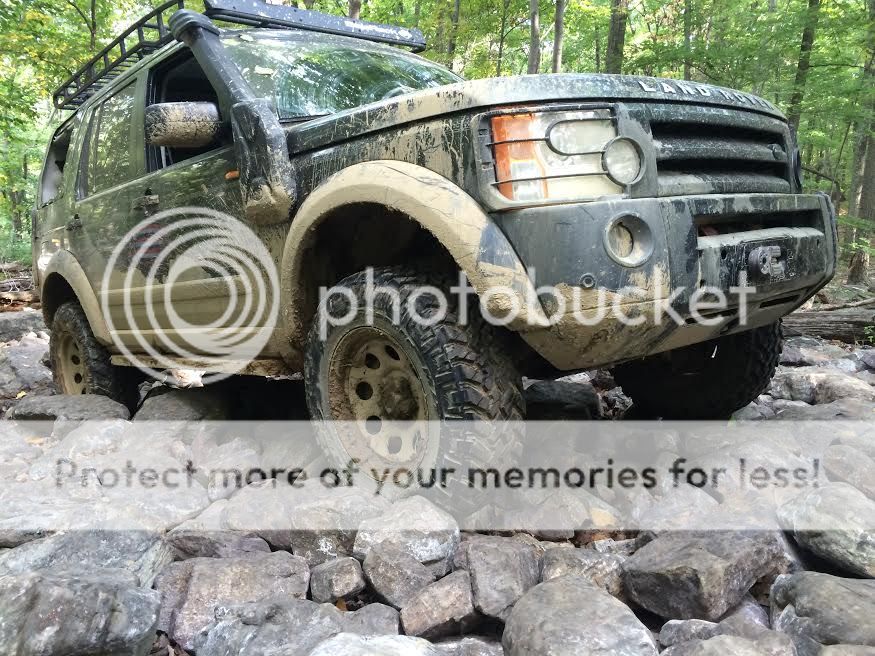

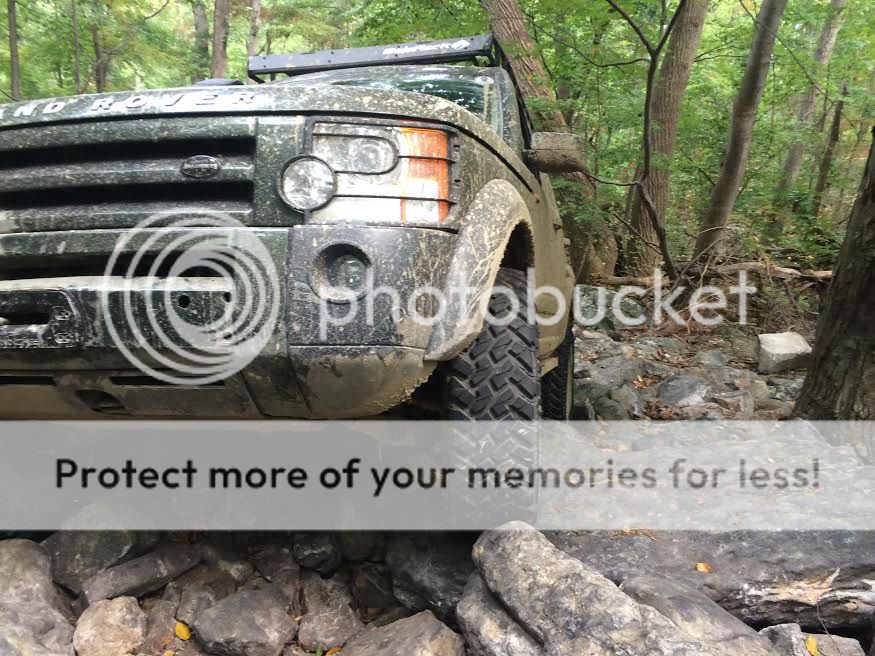

Project LR3 tackled most of the trail with ease. I felt in sync with the computer that directs the traction control and the rear locker. Sand mode became my best friend as its program was closest to my driving style. I knew just how much throttle to apply making the computer dance to my song. I was the pied piper and the gas pedal was my flute. My personal confidence in the LR3 was at an all time high. With this awesome feeling of confidence between myself and the LR3, I made a moronic decision to attempt a little trail called Corum. Here’s a little view of what I got myself into!

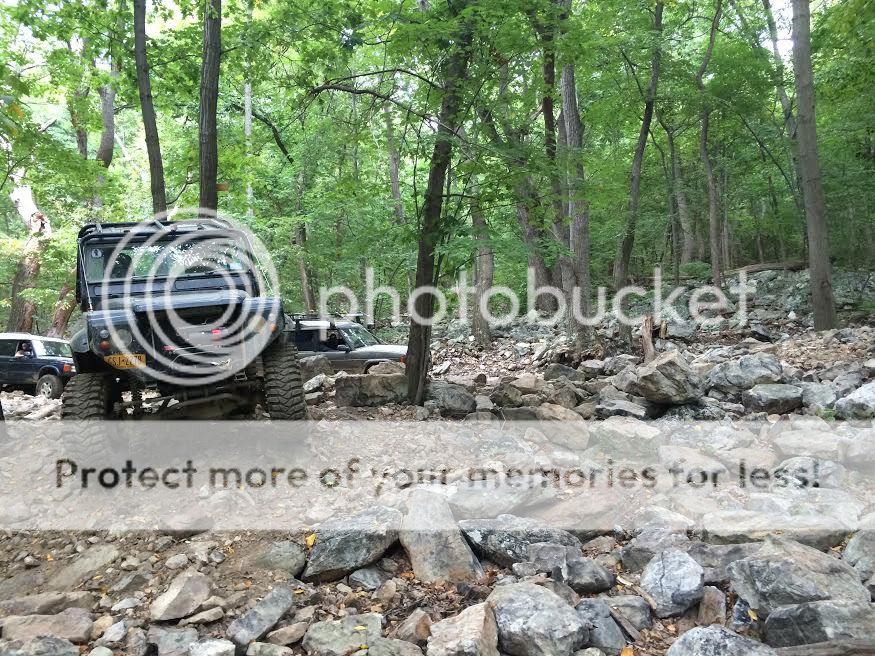

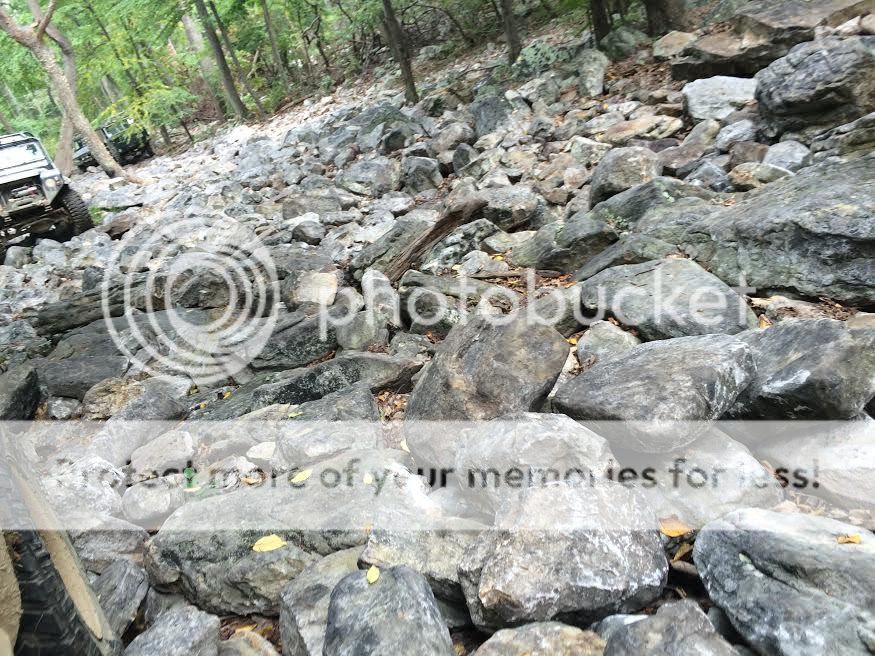

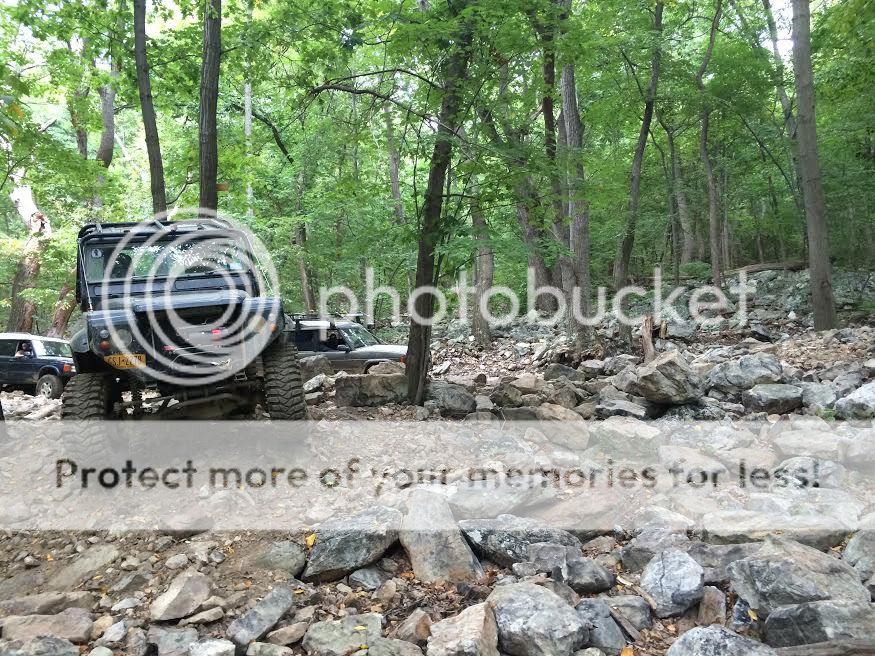

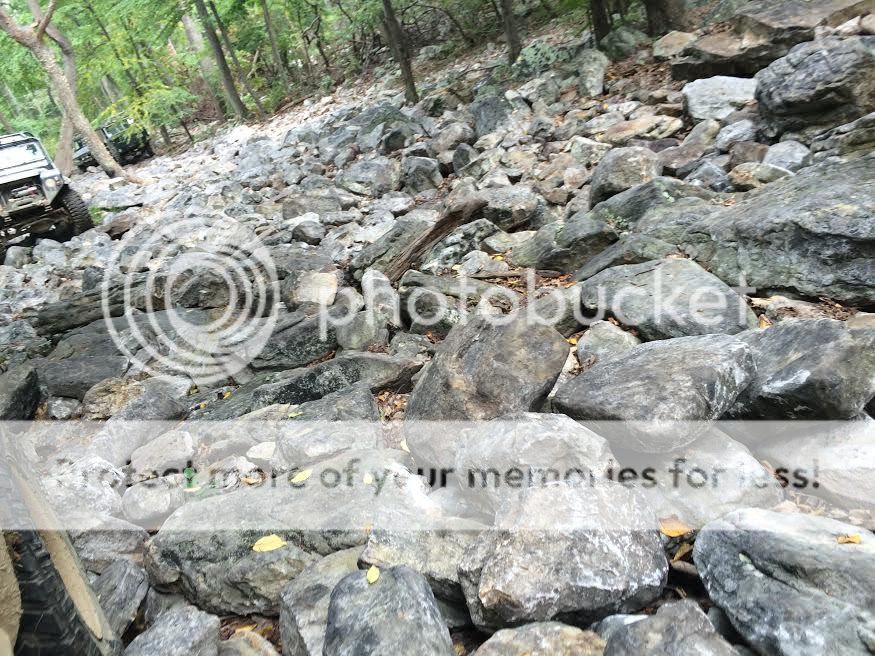

Corum is about a mile long and nothing but rocks stacked on top of rocks. Sitting at the bottom looking up I started to realize I brought a hamburger to a gunfight.

My confidence was starting to shrivel like George Castanza in the cold pool. Thankfully, I was in good company. Charles Galpin and Jason Lavender offered to take point in their D90’s. They have conquered this trail many times in the past and both are excellent spotters.

Just in case things went tits up I brought along some extra muscle. Simon Schofield in his FC101

and Andy Liwush in his massive hybrid series.

You starting to feel my hamburger analogy now??

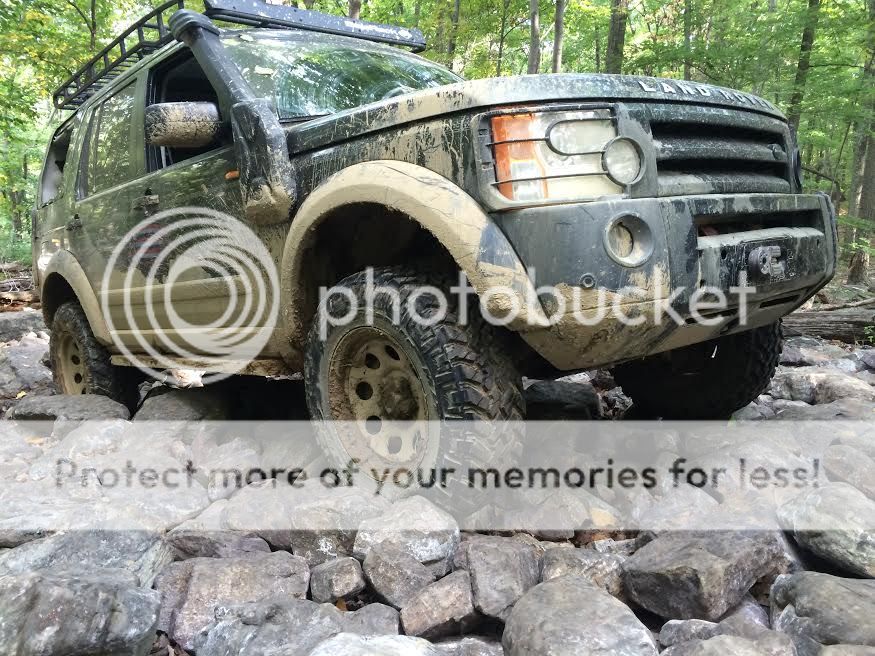

The first 100 yards or so were not too bad. I just took my time and focused on keeping the truck up on the tall rocks.

The LR3 chugged along over the ever moving slippery rocks. It just kept climbing over everything on the trail. The air infused independent cross-link suspension was a big asset. The truck stayed level and kept the wheels on the ground that had traction. The LR3’s advantage was the extra ground clearance from not having a solid axle. No differentials dragging in the middle of the truck; what a concept.

Further down the trail, we went, the tougher it became. It wasn't long before Corum took its first victim. Charles Galpin lost a motor mount. This took him out of the lead position.

Luckily, for Charles, we had quite a few onlookers waiting for LR3 carnage. Since there was no carnage to be found Charles had no problem finding some helping hands to get his truck back up and going.

As the rock sizes on the trail just kept increasing it became very difficult to keep the truck on track. Every time you put a tire on the top rock the ones below would slide and shift underneath. The rocks would not sit still. With the end of the trail was in sight things went sideways for project LR3. Rocks were becoming too large for the tires to stay on the ground. The sill mount rock sliders were not handling the abuse well. They did a good enough job to protect the truck but, with all the stress that was being put on them they were starting to fold up into the bodywork. Additionally, the entire time, I was hyper-focused on not letting a rock crush the exposed air compressor.

As I pushed forward we had a major failure. The truck was articulating as it should but due to the extraordinary amount of flex the rear passenger airbag deflated all the way. This allowed the height sensors attached to lift rods to go past the plausible amount the computer could see. The end result was the suspension went into a panic. From the computer’s point of view, the tire was inside the passenger compartment. With the lift rods on we need to remember that we are tricking the computer. This is all well and good but it also allows the sensors to go past their plausible range. That’s when computers become unbelievably unhappy, then it's game over.

There I was stuck on a rock with the tire jammed into the bodywork going nowhere. If the lift rod had not pushed the height sensor out of range the computer would've put pressure back into the system, then picking the truck off the surface and allowing me to climb the obstacle.

Outcomes the mighty red winch! The truck is freed from its predicament and upon further discovery, things were worse than I originally had thought.

The air suspension would not come back online even when the tire was firmly placed on solid ground. With a completely deflated air bag, the computer was not going to put any more air in until the suspension was in a position that the computer would recognize as relevant. There are a couple of ways to accomplish this. One was to jack the truck up to put the height center back in the realm of reality. Or choice two, disconnect the rod and move the height sensor by hand. Given the very unstable area we had for the Hi-lift it appeared that it was easier to slide under the side of the truck and move the height sensor by hand. After this minor setback, we scouted out the easiest path to get the LR3 free from the clutches of Coram.

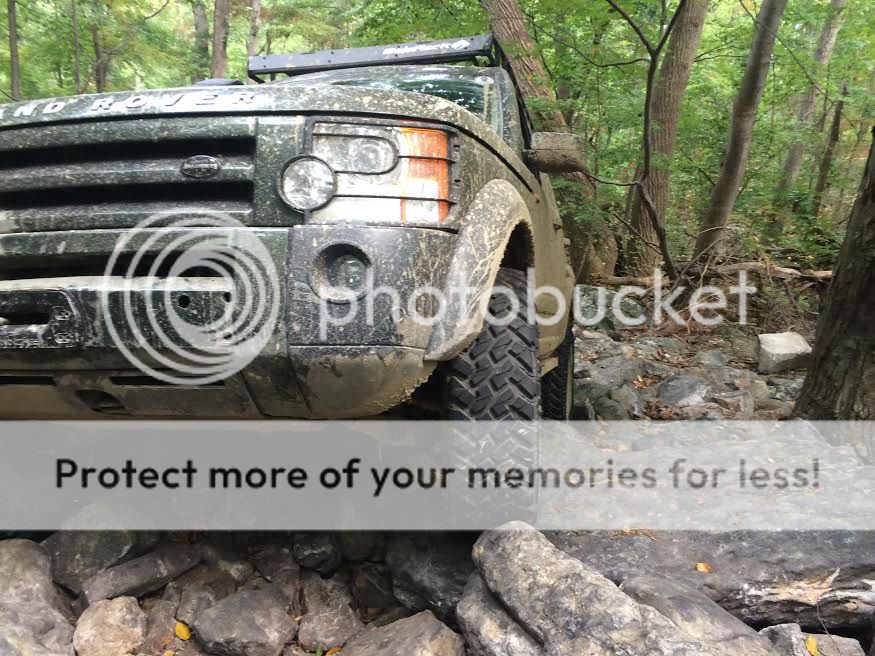

Although, all the LR3 did not make it all the way to the end; it got damn close on a set of wannabe 33-inch tires. The great takeaway from this little event was; we now know there is a need to find a way to extend the bump stops, so this would never happen ever again. I leave ya with this poser pic of an LR3 trying to fit in with the big boys.

Armed with my new monster winch and gained confidence in the truck. I headed off to the conclave.

The conclave was held at The Cove in VA. Most of the trails I saw were hard packed dirt. Trails are tightly woven through the trees with many elevation changes. If you have a chance to attend an event here I would recommend it.

Project LR3 tackled most of the trail with ease. I felt in sync with the computer that directs the traction control and the rear locker. Sand mode became my best friend as its program was closest to my driving style. I knew just how much throttle to apply making the computer dance to my song. I was the pied piper and the gas pedal was my flute. My personal confidence in the LR3 was at an all time high. With this awesome feeling of confidence between myself and the LR3, I made a moronic decision to attempt a little trail called Corum. Here’s a little view of what I got myself into!

Corum is about a mile long and nothing but rocks stacked on top of rocks. Sitting at the bottom looking up I started to realize I brought a hamburger to a gunfight.

My confidence was starting to shrivel like George Castanza in the cold pool. Thankfully, I was in good company. Charles Galpin and Jason Lavender offered to take point in their D90’s. They have conquered this trail many times in the past and both are excellent spotters.

Just in case things went tits up I brought along some extra muscle. Simon Schofield in his FC101

and Andy Liwush in his massive hybrid series.

You starting to feel my hamburger analogy now??

The first 100 yards or so were not too bad. I just took my time and focused on keeping the truck up on the tall rocks.

The LR3 chugged along over the ever moving slippery rocks. It just kept climbing over everything on the trail. The air infused independent cross-link suspension was a big asset. The truck stayed level and kept the wheels on the ground that had traction. The LR3’s advantage was the extra ground clearance from not having a solid axle. No differentials dragging in the middle of the truck; what a concept.

Further down the trail, we went, the tougher it became. It wasn't long before Corum took its first victim. Charles Galpin lost a motor mount. This took him out of the lead position.

Luckily, for Charles, we had quite a few onlookers waiting for LR3 carnage. Since there was no carnage to be found Charles had no problem finding some helping hands to get his truck back up and going.

As the rock sizes on the trail just kept increasing it became very difficult to keep the truck on track. Every time you put a tire on the top rock the ones below would slide and shift underneath. The rocks would not sit still. With the end of the trail was in sight things went sideways for project LR3. Rocks were becoming too large for the tires to stay on the ground. The sill mount rock sliders were not handling the abuse well. They did a good enough job to protect the truck but, with all the stress that was being put on them they were starting to fold up into the bodywork. Additionally, the entire time, I was hyper-focused on not letting a rock crush the exposed air compressor.

As I pushed forward we had a major failure. The truck was articulating as it should but due to the extraordinary amount of flex the rear passenger airbag deflated all the way. This allowed the height sensors attached to lift rods to go past the plausible amount the computer could see. The end result was the suspension went into a panic. From the computer’s point of view, the tire was inside the passenger compartment. With the lift rods on we need to remember that we are tricking the computer. This is all well and good but it also allows the sensors to go past their plausible range. That’s when computers become unbelievably unhappy, then it's game over.

There I was stuck on a rock with the tire jammed into the bodywork going nowhere. If the lift rod had not pushed the height sensor out of range the computer would've put pressure back into the system, then picking the truck off the surface and allowing me to climb the obstacle.

Outcomes the mighty red winch! The truck is freed from its predicament and upon further discovery, things were worse than I originally had thought.

The air suspension would not come back online even when the tire was firmly placed on solid ground. With a completely deflated air bag, the computer was not going to put any more air in until the suspension was in a position that the computer would recognize as relevant. There are a couple of ways to accomplish this. One was to jack the truck up to put the height center back in the realm of reality. Or choice two, disconnect the rod and move the height sensor by hand. Given the very unstable area we had for the Hi-lift it appeared that it was easier to slide under the side of the truck and move the height sensor by hand. After this minor setback, we scouted out the easiest path to get the LR3 free from the clutches of Coram.

Although, all the LR3 did not make it all the way to the end; it got damn close on a set of wannabe 33-inch tires. The great takeaway from this little event was; we now know there is a need to find a way to extend the bump stops, so this would never happen ever again. I leave ya with this poser pic of an LR3 trying to fit in with the big boys.

Can't your IID tool put the suspension computer in a diagnostic mode (there's a name for it) that forces the suspension to raise?

Can't your IID tool put the suspension computer in a diagnostic mode (there's a name for it) that forces the suspension to raise?

Yes it can. Back when this happened I was not as proficient with the Gap tool.

Funny how a $500 D1 with about $3k in mods can walk that trail like a highway.

Funny because when I had a D1 it was me who did most of the walking.

Funny because when I had a D1 it was me who did most of the walking.

To Dan you're either a shit driver or didn't have enough GoPros.