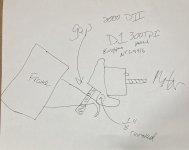

ETA: I used diesel D2 mounts for his project, (2000 D2, 237K miles) and the D2 TDi mounts I received Were Not a perfect fit. I had to slightly modify the mounts to fit. Pictures, the process, part numbers to follow. In response to Juke179R, I'm going to look further into parts numbers; there might be a difference between 300tdi and TD5 mounts for the D2.

Original Post started here: I'm in the middle of HGs on my 00 D2 after noticing a passenger side coolant leak. When I crawled under the truck to remove the exhaust manifolds from the Y pipe, I noticed all both motor, and transfer case mounts are shot; the motor is both kinked/turned and about an inch forward. My son rear ended a pick up last summer and I suspect the jolt from the bump, or my off roading since, has caused the problem.

I replaced the drivers side a number years ago; the remaining mounts are 23 years old.

I've got the passenger side nut off, but I seem to recall that the trick to break torque on the drivers side was to get a wrench in there and use a bottle jack (at least that's my current plan) to break torque.

Need your Tips and Tricks for the drivers side, and the transfer case mounts.

I've got a transmission lift, two 3 ton floor jacks, and a couple of bottle jacks. Ive also got an engine lift, but would have to roll the truck out of the garage to use it.

thanks in advance, mv

Original Post started here: I'm in the middle of HGs on my 00 D2 after noticing a passenger side coolant leak. When I crawled under the truck to remove the exhaust manifolds from the Y pipe, I noticed all both motor, and transfer case mounts are shot; the motor is both kinked/turned and about an inch forward. My son rear ended a pick up last summer and I suspect the jolt from the bump, or my off roading since, has caused the problem.

I replaced the drivers side a number years ago; the remaining mounts are 23 years old.

I've got the passenger side nut off, but I seem to recall that the trick to break torque on the drivers side was to get a wrench in there and use a bottle jack (at least that's my current plan) to break torque.

Need your Tips and Tricks for the drivers side, and the transfer case mounts.

I've got a transmission lift, two 3 ton floor jacks, and a couple of bottle jacks. Ive also got an engine lift, but would have to roll the truck out of the garage to use it.

thanks in advance, mv

Last edited: