If I can make the jag blower and intercoolers fit with a customized lower plenum / intake... I make just make a few and sell em.

Preferable clutch brands.

- Thread starter 4Runner

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hey. It’s my thread.If I had the budget, I'd be very interested to see if Darton sleeves could be used to poke the displacement and use ~3.8 buick pistons and a buick 350 crank... I am guessing some significant rod clearance issues would need to be dealt with. This would require the 3.9/4.2 block though..which of course is sans cross-bolts. If using the 4/4.6 then I am guessing a lot crank work would be required to make it all fit. I have not seen them all in a room together so... I just dunno. I reached out to D&D but have not heard back.

*Man, I have seriously failed to help keep this Preferable Clutch Brands post on track! I will end my non-related discussion here.

300 Buick heads will bolt right on.. and they're still aluminum in that first year after they killed off the 215 (I forget... '67 or '64). Apparently those make a lot of power and have meat to port. The accessory mounts will surely need some "customization" though.

But again, a blower will more than make up for it; remember, I am not trying to make 500hp.. just 300 (all at very low rpm..which *does* mean LOTS of torque, I know.. but.. details).

But again, a blower will more than make up for it; remember, I am not trying to make 500hp.. just 300 (all at very low rpm..which *does* mean LOTS of torque, I know.. but.. details).

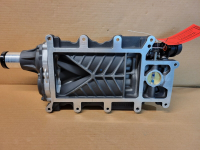

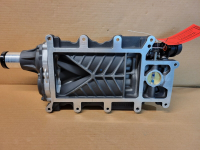

re: Jag blower

This is the one I am eyeballin (not this physical one, but.. you get it): https://www.ebay.com/itm/235277191082

I have no idea if that snout clears the alternator, distributor, etc... but it's a start. Clearly the inlet will need some customization for the throttle body, MAF, airbox, etc. But the intercoolers look cool

This is the one I am eyeballin (not this physical one, but.. you get it): https://www.ebay.com/itm/235277191082

I have no idea if that snout clears the alternator, distributor, etc... but it's a start. Clearly the inlet will need some customization for the throttle body, MAF, airbox, etc. But the intercoolers look cool

Last edited:

Is that for the straight 6 motor? Maybe a centrifugal blower would be the ticket. Not sure an intercooler would be necessary at low boost. I know it’s always better to have one than not, but you could get away with it at 4 or 5 psi. That would be really cool. If I am missing the point that you want it to be an “ all English” theme, then just let me know. Lolre: Jag blower

This is the one I am eyeballin (not this physical one, but.. you get it): https://www.ebay.com/itm/235277191082

I have no idea if that snout clears the alternator, distributor, etc... but it's a start. Clearly the inlet will need some customization for the throttle body, MAF, airbox, etc. But the intercoolers look coolView attachment 65770

Nope. They are useless at low RPM.. unless you put a *tiny* pulley on it and spin the everloving snot out of it. I don't see that as feasible. twin, very small turbos would be a more effective solution for this low RPM, low boost bar top beauty.Maybe a centrifugal blower

Intercoolers help even at boost levels in the 5psi range. I imagine they do at lower squeeze but there is certainly a diminishing effect...which crosses over into negative "help" territory at low and off-boost levels, because of the increased pressure drop (inlet air resistance) that come with blowing and sucking air through a radiator and all that inlet plumbing.Not sure an intercooler would be necessary at low boost. I know it’s always better to have one than not, but you could get away with it at 4 or 5 psi.

I am much more experienced with turbo systems (fabricating and fitting) than positive displacement (blowers) superchargers.. I know I do not want to have more heat generators under the hood.. the damned wagon gets heatsoaked on any drive over a couple hours anyways.. So, I am disinclined to use turbos; though chinese ones are DIRT cheap on ebay... I am not a fan (hah) of spinning really cheap shit at 80,000 RPM near anything I care much about.

As far as boost levels go: I am thinking of shooting for 8-10psi, if I can intercool it. The engine only has what, 9.5:1 compression? With the addition of a knock sensor to kill timing and inject some water/alc, that should be livable. If I go down this path, I'd want the little engine to think it's at least 1/2 again bigger than it actually it (~7.5psi).

I chased this little snippet from the (now defunct?) ToddCo:

that price was from ~12 years ago. But it illuminates what a "some profit included" price was, to build it. I am gonna try to get ahold of this guy (Todd?) to pick his brain on the "poke" part of his poke & stroke.

Land Rover 5.0HO Land Rover 5.0HO engine, 320HP 340 FTLBS torque. Looking for tire smoking power for your Land Rover? We start with a base Land Rover block stroke it, stuff in a 300 crank, longer connecting rods, larger pistons, 300 heads, matched fuel injectors, blue printed , balanced, ported and polished. Engine is complette and set up for direct bolt in. Please contact us with any questions. $6,495.95 LR5OHO3 |

that price was from ~12 years ago. But it illuminates what a "some profit included" price was, to build it. I am gonna try to get ahold of this guy (Todd?) to pick his brain on the "poke" part of his poke & stroke.

Regarding the supercharger.. That GT500 unit (2005-2010) looks really interesting: the snout looks like it might just make it between the alternator and the distributor.. and the throttle plate (with or without the angled extension) it kinda in the right place.

This is a much larger blower than what is needed.. but that means it would be easy to make low rpm boost. Put a blowoff valve on other sides of the throttle, along with it's built-in no-load/light-load bypass valve, and you've maybe got something that could provide ~10psi at 1200rpm.. and taper it down to 6-7psi at the top ~4500 or so.. to grant some leniency to the bottom end. Heck, using the V8 injector horsepower rule [16 * Inj_Lb/hr] and even the stock injectors are up to the task... given I am talking below 4500 RPM power. The weak stocker 19lb (@43.5psi) injectors (I have the multi-hole disks on mine, but they're stock otherwise) can deliver ~300hp with a slight bump to the stock regulator (mine delivers 32-35psi).

It's a girthy beast but maybe it can be made to fit. Here's one:

Maybe even adapt that electric throttle to cable-actuated... it's pretty low profile, but you can see the elbow I'm referring to in this shot:

This is a much larger blower than what is needed.. but that means it would be easy to make low rpm boost. Put a blowoff valve on other sides of the throttle, along with it's built-in no-load/light-load bypass valve, and you've maybe got something that could provide ~10psi at 1200rpm.. and taper it down to 6-7psi at the top ~4500 or so.. to grant some leniency to the bottom end. Heck, using the V8 injector horsepower rule [16 * Inj_Lb/hr] and even the stock injectors are up to the task... given I am talking below 4500 RPM power. The weak stocker 19lb (@43.5psi) injectors (I have the multi-hole disks on mine, but they're stock otherwise) can deliver ~300hp with a slight bump to the stock regulator (mine delivers 32-35psi).

It's a girthy beast but maybe it can be made to fit. Here's one:

New Roush Supercharger Fits 2005-2010 Mustang GT 4.6L R07050102 P51AH-6F066-AB | eBay

ITEM IS STILL WRAPPED IN THE ORIGINAL BOX -- WE OPENED FOR PICS. THIS IS NOT THE COMPLETE KIT.

www.ebay.com

Maybe even adapt that electric throttle to cable-actuated... it's pretty low profile, but you can see the elbow I'm referring to in this shot:

It turns out there's a cast (twin) turbo manifold made by Boost Performance:

Range Rover v8, Rover v8 Twin Turbo exhaust headers F/S - by Boost Performance. | eBay

They'll never flex, warp or crack unlike a welded steel item. This makes them more suitable for modern rover cylinder heads. The head flanges are also quite thick which allows extra material to be removed if you want to make the exhaust ports taller.

www.ebay.co.uk

It turns out there's a cast (twin) turbo manifold made by Boost Performance:

Guess who has a set of those coming?

ME, just ordered a pair last week. I am sitting on a custom sleeved .20 over block with custom made low compression JE pistons and Potter rods. My son keeps sending me videos of engines grenading saying thats me.

Wow, nice. The 0.20 over is what I'd like to talk about. Have you looked into those new Dalton interlocking sleeves (MID) that require **MAJOR** machining to the block? I don't know if it's even feasible but.. it looks pretty awesome ( https://dartonsleeves.com/tech-publications/mid-information/ ).

I just got off the phone with the guy at D&D. He appears to have a LOT of experience building these engines. He essentially said: build a 4.6 shortblock and bolt your (if late/compatible INTERIM) 3.9 heads, front & back fiddlybits on it.. with a "stage 2" cam and call it a day.

He said the 300 crank idea was born out of the 80's era when there was no 4.6. He said the same guy that attempted to make the 300 crank fit into the 3.9 block also tried the 350 crank..with no success on either attempt.

He also did not recommend the blower (at least at ~7-10psi) either because I'd be hard pressed to keep the gaskets from lifting/failing. Though he did mention some fancy gaskets that may help.. so I'll look into that (I am quite familiar with o-ring'd gaskets and that is not what he mentioned).

Regarding hydraulic roller cams.. he said it will be very difficult finding blanks and harder to find the right profiles for the application (low rpm, boosted). While that may be true, that does not mean it's not possible. That said, I will likely go with a slightly beefed up "stage 2" cam as he suggested. Again, I am trying to make low end power, not high rpm breathing. ...so that needs some more thought.

I just got off the phone with the guy at D&D. He appears to have a LOT of experience building these engines. He essentially said: build a 4.6 shortblock and bolt your (if late/compatible INTERIM) 3.9 heads, front & back fiddlybits on it.. with a "stage 2" cam and call it a day.

He said the 300 crank idea was born out of the 80's era when there was no 4.6. He said the same guy that attempted to make the 300 crank fit into the 3.9 block also tried the 350 crank..with no success on either attempt.

He also did not recommend the blower (at least at ~7-10psi) either because I'd be hard pressed to keep the gaskets from lifting/failing. Though he did mention some fancy gaskets that may help.. so I'll look into that (I am quite familiar with o-ring'd gaskets and that is not what he mentioned).

Regarding hydraulic roller cams.. he said it will be very difficult finding blanks and harder to find the right profiles for the application (low rpm, boosted). While that may be true, that does not mean it's not possible. That said, I will likely go with a slightly beefed up "stage 2" cam as he suggested. Again, I am trying to make low end power, not high rpm breathing. ...so that needs some more thought.

I just talked to Darton Sleeves and am waiting for a callback from their main installer; he said their MID (Modular Integrated Deck) product might be interesting for the 4/4.6 because it would eliminate the cylinder cracking/pin-holes completely (the aluminum cylinders are basically removed as part of the conversion process). If it *is* doable, it would breath new life into these blocks. ...and enable larger bores.

Lets see whats possible.

Lets see whats possible.

Do they have a current website?just ordered a pair last week

I just got off the phone with Steve at Race Engine Development... the outfit that does most of the custom engine work (and sleeve design, I take it) for Darton. He said the MID solution may or may not work for the rover block:

The Bad:

- The Bad: Closed Deck (dry sleeve). He said some closed deck blocks don't work well with this setup.. because the machining process compromises the deck integrity too much; this is especially try for 5 bolt cylinders (LS blocks, for example). The only way is to FAFO...

- He'd need a lab-rat block to try it on.. and don't expect this first block to survive the experiment; it will cost about ~$5K all-in (machining, design, sleeves...excluding shipping and the block). Though he said if it went well, this block may work out.

- Head bolt bosses need to be longer than two inches... I am not sure how long they are, but the outer bosses on the 3.9 look like ~2" or so.

- It is a six month turnaround from when the Go Button is pressed. Maybe less, not more.. but that's his Safe-Guestimate for timeframe.

The Good:

- The rover, being a "ten bolt" block, is configured in a 4-square bolt pattern..which is ideal for the MID conversion

- The MID seals in the bottom of the cylinder, very well.. and so water intrusion is a non-issue

- The MID configuration will allow for a LOT of bore increase...upwards of 4.0" (leaving 0.24" between the interlocking sleeves) making (5.3L) 325cu-in possible with the stock 4.6 crank.

- Way better cooling of the upper cylinder/chamber area...e.g.: less detonation (converts the engine to a wet sleeve).

- No liner slippage...

And then, for crazy stuff, there's this:

triumphroverspares.com.au

triumphroverspares.com.au

**6L ROVER V8 RACE ENGINE** - turbo spec block ($POA) UPDATED CYL HEAD PICS - Triumph Rover Spares

THICK WEB TURBO ROVER BLOCK, CUSTOM SLEEVES WITH 4" BORE, VERY RARE AND HARD TO GET ENGINE BLOCK, ONLY LIMITED NUMBERS MADE CUSTOM MADE TRS SPEC FORGED PISTON WITH LINE 2 LINE SKIRT COATING NEW CNC CYLINDER HEAD PORT PROGRAM SPECIFICALLY DESIGNED FOR THIS BORE AND STROKE COMBINATION FEATURING...

triumphroverspares.com.au

triumphroverspares.com.au

Wow, nice. The 0.20 over is what I'd like to talk about. Have you looked into those new Dalton interlocking sleeves (MID) that require **MAJOR** machining to the block? I don't know if it's even feasible but.. it looks pretty awesome ( https://dartonsleeves.com/tech-publications/mid-information/ ).

I just got off the phone with the guy at D&D. He appears to have a LOT of experience building these engines. He essentially said: build a 4.6 shortblock and bolt your (if late/compatible INTERIM) 3.9 heads, front & back fiddlybits on it.. with a "stage 2" cam and call it a day.

He said the 300 crank idea was born out of the 80's era when there was no 4.6. He said the same guy that attempted to make the 300 crank fit into the 3.9 block also tried the 350 crank..with no success on either attempt.

He also did not recommend the blower (at least at ~7-10psi) either because I'd be hard pressed to keep the gaskets from lifting/failing. Though he did mention some fancy gaskets that may help.. so I'll look into that (I am quite familiar with o-ring'd gaskets and that is not what he mentioned).

Regarding hydraulic roller cams.. he said it will be very difficult finding blanks and harder to find the right profiles for the application (low rpm, boosted). While that may be true, that does not mean it's not possible. That said, I will likely go with a slightly beefed up "stage 2" cam as he suggested. Again, I am trying to make low end power, not high rpm breathing. ...so that needs some more thought.

I have had 9 flat tappet cam and lifter failures in the last 4 years. After the second cam and 3 sets of lifters and 4 iterations of rocker setups i gave up on a flat tappet cam in annabelle. I just want her to run reliably and the only way i saw it going was to go full roller engine. So i went on a mission. I got a roller 215 billit and after 8 machine shops i found one that said "Send it to me!" after months and months he had the nose cut to match the short nose and did a custom grind on it for mid range power 2000-5000rpm. Nothing crazy on the grind but as aggressive as he could within that rpm range. I just asked him last week if he could replicate it and now that he knows what to do the answer is yes. it surpised me on the price too. much cheaper than i was expecting. yesterday i fit my rockers and was able to get a pushrod measurement. Called Manton pushrods and have a set being made. I cant wait to get them and have her running. i have been fighting this cam issue for almost 2 years now.Wow, nice. The 0.20 over is what I'd like to talk about. Have you looked into those new Dalton interlocking sleeves (MID) that require **MAJOR** machining to the block? I don't know if it's even feasible but.. it looks pretty awesome ( https://dartonsleeves.com/tech-publications/mid-information/ ).

I just got off the phone with the guy at D&D. He appears to have a LOT of experience building these engines. He essentially said: build a 4.6 shortblock and bolt your (if late/compatible INTERIM) 3.9 heads, front & back fiddlybits on it.. with a "stage 2" cam and call it a day.

He said the 300 crank idea was born out of the 80's era when there was no 4.6. He said the same guy that attempted to make the 300 crank fit into the 3.9 block also tried the 350 crank..with no success on either attempt.

He also did not recommend the blower (at least at ~7-10psi) either because I'd be hard pressed to keep the gaskets from lifting/failing. Though he did mention some fancy gaskets that may help.. so I'll look into that (I am quite familiar with o-ring'd gaskets and that is not what he mentioned).

Regarding hydraulic roller cams.. he said it will be very difficult finding blanks and harder to find the right profiles for the application (low rpm, boosted). While that may be true, that does not mean it's not possible. That said, I will likely go with a slightly beefed up "stage 2" cam as he suggested. Again, I am trying to make low end power, not high rpm breathing. ...so that needs some more thought.

As for sleeves they are easily done. .20 over is no issue. Pistons, rings and rods can be made or sourced. The turbo project was just something i stumbled into.